-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

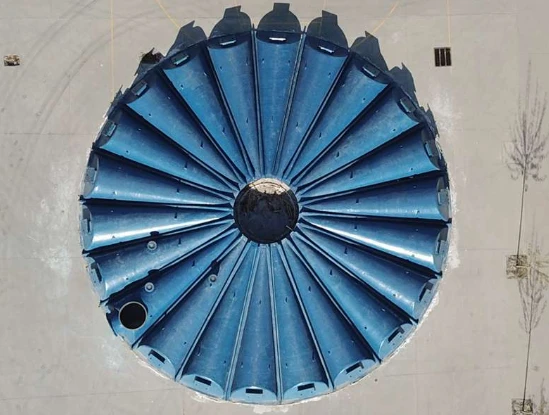

1. frp flange blind

Understanding FRP Flange Blinds A Comprehensive Overview

In various engineering and industrial applications, the seamless integration of components is vital for ensuring safety, reliability, and efficiency. Among these components, the FRP (Fiber Reinforced Polymer) flange blind plays a critical role, particularly in systems involving pipes and tanks. This article explores what FRP flange blinds are, their construction, advantages, applications, and maintenance considerations.

What is an FRP Flange Blind?

An FRP flange blind is a plate or disc made from fiber-reinforced polymer that is used to seal the end of a pipe or fitting. These blinds are designed to prevent the flow of fluids through the pipe, making them essential for maintenance, inspection, and safety purposes. Flange blinds are typically used in scenarios where a portion of a system may need to be temporarily isolated for repairs, modifications, or inspections.

Construction and Materials

FRP flange blinds are constructed from a composite material that consists of a polymer matrix reinforced with fiber, typically glass fibers. This unique composition gives FRP blinds several advantageous properties. The manufacturing process often includes molding techniques that ensure precision and reliability, enabling these blinds to fit snugly against the flanges of pipes.

The choice of materials in FRP is crucial, as it affects the blind's strength, weight, chemical resistance, and durability. The polymer component provides resistance to corrosion, while the reinforcement contributes to enhanced mechanical properties, ensuring that the blind can withstand the stresses it may encounter in various environments.

Advantages of FRP Flange Blinds

1. Corrosion Resistance One of the most significant benefits of using FRP materials is their resistance to corrosion. Unlike metal options, which can rust over time, FRP flange blinds remain unaffected by many corrosive chemicals, making them ideal for use in industries such as chemical processing, oil and gas, and wastewater management.

2. Lightweight FRP materials are significantly lighter than metals, which simplifies handling and installation. This attribute can lead to reduced labor costs and simplified transportation to job sites.

3. High Strength-to-Weight Ratio Despite being lightweight, FRP flange blinds offer excellent strength. This property allows them to withstand considerable pressure and temperature variations, ensuring safety and reliability in demanding applications.

1. frp flange blind

4. Customizability Manufacturers can produce FRP flange blinds in various sizes and shapes to meet specific requirements. This customizability ensures that engineers and designers can find the perfect fit for their projects, no matter how unusual the specifications may be.

5. Thermal Insulation FRP materials offer good thermal insulation, which can help maintain the temperature of the fluids within the pipe and improve overall energy efficiency.

Applications

FRP flange blinds are widely utilized across numerous sectors, including

- Oil and Gas Used for isolating sections of pipelines, especially in offshore and corrosive environments. - Water Treatment Serving as temporary barriers in hydrocarbon processing and wastewater facilities. - Chemical Manufacturing Protecting against leaks and spills during maintenance or inspection operations. - Pharmaceuticals Ensuring that systems remain sterile when not in use, reducing contamination risks.

Maintenance Considerations

While FRP flange blinds are designed to be highly durable, regular inspection and maintenance are still essential. Users should routinely check for any signs of wear, damage, or chemical degradation. Although FRP is resistant to many chemicals, it is still important to ensure compatibility with the specific substances being conveyed in the connected pipes.

When installing or removing an FRP flange blind, care should be taken to avoid damaging the gasket surfaces, as this can lead to leaks. Proper torque specifications should be followed to ensure even and adequate sealing without over-compressing the material.

Conclusion

FRP flange blinds are invaluable components in many industrial applications. Their unique properties provide enhanced performance, safety, and economic benefits, making them a preferable choice over traditional metal options. As industries continue to innovate and evolve, the demand for and reliance on composite materials like FRP will likely grow, reinforcing the need for understanding and utilizing these crucial components effectively.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025