-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Design and Maintenance of Acid Storage Tanks for Industrial Applications

The Importance of Acid Storage Tanks in Industrial Applications

Acid storage tanks play a crucial role in various industrial applications, particularly within chemical manufacturing, pharmaceuticals, and wastewater treatment facilities. These specialized containers are designed to safely store a wide range of corrosive acids, ensuring that operations run smoothly while minimizing risks associated with leaks, spills, and contamination.

Design and Construction

The design and construction of acid storage tanks are critical to their effectiveness and safety. These tanks are typically made from materials that can withstand the corrosive nature of acids, such as high-density polyethylene (HDPE), fiberglass reinforced plastic (FRP), and certain grades of stainless steel. The choice of material depends on the specific type of acid being stored, as different acids can have varying degrees of reactivity.

Furthermore, these tanks are generally equipped with secondary containment systems, which provide an additional layer of protection against potential leaks. This might include a bunded area or a double-walled tank design, which captures any leaked material and prevents it from reaching the environment. Regulatory guidelines often dictate the design specifications for acid storage tanks to ensure compliance with safety standards.

Regulatory Compliance

The storage of acids is subject to a variety of regulations aimed at protecting health and the environment. Organizations like the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) in the United States impose strict guidelines that must be followed. Compliance with these regulations not only enhances safety but also helps organizations avoid substantial fines and legal liabilities.

Routine inspections, maintenance, and proper employee training are integral to compliance. Companies must ensure that their personnel are well-versed in the handling of hazardous materials and that regular safety drills are conducted. Documentation of these practices is crucial not only for regulatory audits but also for fostering a culture of safety within the workforce.

acid storage tank

Risk Management

Effective risk management strategies are essential when dealing with acid storage tanks. One primary concern is the risk of tank failure, which can lead to catastrophic spills and expose employees to harmful fumes. Regularly scheduled maintenance checks and thorough inspections can identify potential issues early, reducing the likelihood of failures.

Furthermore, the installation of monitoring systems, such as level sensors and leak detection systems, can provide real-time data about the conditions within the tank. This technology enables prompt responses to any irregularities, enhancing overall safety.

Environmental Considerations

The environmental implications of acid storage cannot be overstated. In the event of a spill, acids can contaminate soil and water supplies, causing significant ecological damage. This is why many facilities are now investing in advanced safety technologies and sustainable practices. By adopting eco-friendly materials and implementing efficient waste disposal methods, businesses can minimize their environmental footprint while still meeting their operational needs.

Conclusion

In conclusion, acid storage tanks are an indispensable component of many industrial operations. Their design and construction must prioritize safety and regulatory compliance to protect both workers and the environment. By adopting robust risk management strategies and investing in new technologies, industries can ensure safe and efficient acid storage. As environmental concerns continue to rise, focusing on sustainable practices in acid management will be vital for the long-term success of these operations. Through diligence and innovation, industries can navigate the complexities of acid storage, ensuring a safer and more sustainable future.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

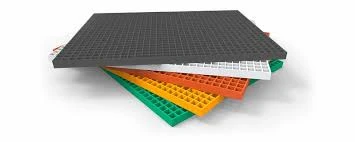

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025