-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Design and Maintenance Considerations for Acid Storage Tanks in Industrial Applications

Understanding Acid Storage Tanks Importance, Design, and Maintenance

Acid storage tanks play a critical role in numerous industries, including pharmaceuticals, chemicals, food processing, and wastewater treatment. These tanks are specifically designed to safely store aggressive materials like sulfuric acid, hydrochloric acid, and other corrosive substances. Given the hazardous nature of these chemicals, it is imperative to have a comprehensive understanding of the importance, design considerations, and maintenance practices related to acid storage tanks.

Importance of Acid Storage Tanks

The primary purpose of acid storage tanks is to provide a secure and reliable means of storing corrosive chemicals. Safety is the foremost consideration; improper storage can lead to leaks, spills, or catastrophic failures that can endanger workers, the environment, and property. Thus, effective storage solutions minimize risks associated with acid handling, ensure compliance with regulations, and protect public health.

From an operational perspective, these tanks enable businesses to manage their acid inventories efficiently. Proper storage allows for consistent production rates, ensuring that the supply chain remains uninterrupted. Additionally, with regular inventory assessments, businesses can plan for procurement more strategically, reducing waste and potentially lowering costs.

Design Considerations

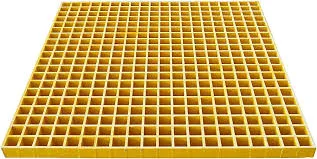

The design of acid storage tanks involves several critical factors. First and foremost is material selection. Tanks must be constructed from materials that can withstand the corrosive nature of the stored substances. Common materials include fiberglass reinforced plastic (FRP), polyethylene, and certain stainless steels. Each material has its benefits and drawbacks, and the choice depends on the specific acid being stored, its concentration, and the storage environment.

Another key consideration is tank size and configuration. The design must accommodate both the volume of acid needed for operations and local regulations regarding capacity. Tanks are often equipped with features such as secondary containment systems to capture any leaks, overflow valves to prevent overfilling, and monitoring systems for real-time visibility of tank levels.

Thermal insulation may also be necessary depending on the ambient conditions and the physical characteristics of the acids stored. Some acids can react with heat, making thermal management a vital part of tank design.

acid storage tank

Safety Measures

Safety systems integrated into acid storage tanks can significantly mitigate risks. For instance, tanks are often fitted with pressure relief valves that release excess pressure safely, preventing explosive scenarios. Additionally, vapor-venting systems are crucial to prevent the build-up of toxic fumes.

Regular inspections and maintenance are essential in ensuring the integrity of the tanks. Routine checks for chemical degradation, corrosion, and structural integrity help to identify potential issues before they result in failures. Additionally, emergency response plans should be in place, outlining procedures for containment and cleanup in the event of an accidental release.

Maintenance Practices

Maintaining acid storage tanks requires diligence and care. Scheduled maintenance should include

1. Visual Inspections Regular checks for signs of corrosion, leakage, and structural issues. 2. Integrity Testing Non-destructive testing methods can help assess the tank's condition, ensuring it can safely hold its contents. 3. Cleaning Protocols Periodic cleaning helps to remove buildup that can lead to leaks or contamination. Proper cleaning agents that are compatible with the stored acid should be used. 4. Record Keeping Documentation of inspections, maintenance, and any incidents is vital for compliance with regulatory standards and for internal assessments.

Proper training for personnel is equally important. Workers must be knowledgeable about the types of acids handled, the specific hazards posed, and the emergency procedures in place. This ensures that everyone involved in the storage and handling of acids is prepared to act responsibly and effectively.

Conclusion

Acid storage tanks represent a vital component of industries that handle corrosive materials. A thorough understanding of their design, safety measures, and maintenance practices is crucial to ensuring both operational efficiency and safety. By prioritizing the proper storage of acids, businesses can protect their workers, the environment, and their bottom line. As regulations continue to evolve and technologies improve, ongoing education and adaptation will be key to maintaining best practices in acid storage tank management.