-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 17, 2025 00:44

Back to list

acid storage tank

Navigating the complexities of acid storage presents numerous challenges and opportunities for businesses in industries such as manufacturing, pharmaceuticals, and agriculture. At the heart of this issue is the acid storage tank, an engineered solution designed to safely contain corrosive substances. Understanding the critical components of these tanks enhances their safe utilization and maintenance, reinforcing both operational efficiency and environmental sustainability.

Adhering to regulatory standards is another critical aspect of managing acid storage tanks. Comprehending laws such as the Environmental Protection Agency's (EPA) regulations or the Occupational Safety and Health Administration's (OSHA) guidelines ensures compliance and fortifies an organization’s reputation as a responsible entity. These guidelines typically include procedures for tank installation, inspection, and maintenance, as well as recommendations for employee safety training. Successful management of acid storage tanks rests not only on the physical components but also on human expertise. Employing skilled technicians trained in chemical handling can significantly mitigate risks, whereas investing in continuous education keeps staff informed about the latest safety protocols and technological advancements. Moreover, incorporating digital solutions elevates the management of acid storage beyond traditional methods. Utilizing Internet of Things (IoT) technology to monitor tank conditions in real-time enhances reaction times to potential problems, minimizes downtime, and extends the lifespan of the storage system. Modern software platforms enable seamless integration with existing enterprise systems, offering predictive maintenance alerts and comprehensive data analytics to improve decision-making. Building a proactive maintenance schedule forms the bedrock of trust and reliability in acid storage. Regularly scheduled inspections and maintenance tasks can detect wear and tear early, preventing costly repairs and ensuring compliance with industry standards. This proactive approach, combined with proper staff training and leveraging technology, results in a robust strategy that optimizes operations while safeguarding human health and the environment. The unique challenges of acid storage highlight the importance of blending expert insight with cutting-edge technology. This synergy cultivates a trustworthy operation that not only meets the immediate demands of chemical containment but anticipates future changes in regulatory landscapes and environmental policies. Organizations that prioritize expertise, trust, and innovation will lead the way in sustainable and safe chemical management, setting benchmarks for industry best practices globally.

Adhering to regulatory standards is another critical aspect of managing acid storage tanks. Comprehending laws such as the Environmental Protection Agency's (EPA) regulations or the Occupational Safety and Health Administration's (OSHA) guidelines ensures compliance and fortifies an organization’s reputation as a responsible entity. These guidelines typically include procedures for tank installation, inspection, and maintenance, as well as recommendations for employee safety training. Successful management of acid storage tanks rests not only on the physical components but also on human expertise. Employing skilled technicians trained in chemical handling can significantly mitigate risks, whereas investing in continuous education keeps staff informed about the latest safety protocols and technological advancements. Moreover, incorporating digital solutions elevates the management of acid storage beyond traditional methods. Utilizing Internet of Things (IoT) technology to monitor tank conditions in real-time enhances reaction times to potential problems, minimizes downtime, and extends the lifespan of the storage system. Modern software platforms enable seamless integration with existing enterprise systems, offering predictive maintenance alerts and comprehensive data analytics to improve decision-making. Building a proactive maintenance schedule forms the bedrock of trust and reliability in acid storage. Regularly scheduled inspections and maintenance tasks can detect wear and tear early, preventing costly repairs and ensuring compliance with industry standards. This proactive approach, combined with proper staff training and leveraging technology, results in a robust strategy that optimizes operations while safeguarding human health and the environment. The unique challenges of acid storage highlight the importance of blending expert insight with cutting-edge technology. This synergy cultivates a trustworthy operation that not only meets the immediate demands of chemical containment but anticipates future changes in regulatory landscapes and environmental policies. Organizations that prioritize expertise, trust, and innovation will lead the way in sustainable and safe chemical management, setting benchmarks for industry best practices globally.

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

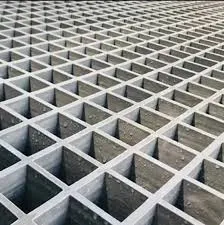

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025