-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Optimized Carbide Conical Button Bits for Enhanced Efficiency in Rock Drilling Applications

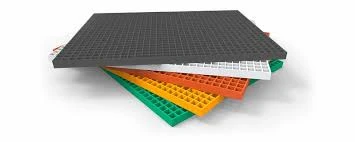

Carbide Conical Button Bits Designed for Efficient Rock Drilling

In the world of rock drilling, efficiency and effectiveness are paramount. The tools used in this demanding environment must withstand extreme conditions while delivering optimal performance. One such tool that has revolutionized the drilling industry is the carbide conical button bit. Known for their durability and precision, these bits are engineered to provide superior drilling capabilities in various geological conditions.

The Design of Carbide Conical Button Bits

Carbide conical button bits are designed with a conical shape, which allows them to penetrate rock effectively. The conical structure enables a larger contact area with the rock, distributing the impact force evenly and reducing wear on the bit itself. Each bit is embedded with tungsten carbide buttons—small, hard tips that are resistant to abrasion and chipping. This unique construction not only enhances the bit's performance but also extends its lifespan, making it a cost-effective choice for drilling operations.

Advantages of Carbide Conical Button Bits

1. Durability The tungsten carbide material is known for its hard-wearing properties. This means that the bits can withstand the harsh conditions of rock drilling, including high temperatures and extreme pressures, without losing their effectiveness. As a result, operators can drill for extended periods without the need for frequent replacements.

2. Versatility Carbide conical button bits are versatile tools that can be used in a variety of applications, from mining and tunneling to construction and geological exploration. They are suitable for different rock types, including hard and abrasive materials, making them a preferred choice for many drilling contractors.

3. Efficiency The design of the conical button bit promotes efficient drilling. The shape allows for better penetration, reducing the overall drilling time and improving productivity. Operators can achieve deeper and more accurate holes in a shorter amount of time, which is crucial in competitive environments.

carbide conical button bits designed for efficient rock drilling ...

4. Reduced Vibration and Noise One of the challenges in rock drilling is managing vibration and noise produced during the drilling process. The design of carbide conical button bits minimizes these issues, leading to a smoother drilling operation. This not only improves the operator's safety and comfort but also reduces the environmental impact of drilling activities.

Applications in the Industry

Carbide conical button bits are used in a wide range of industries, including mining, oil and gas, and civil engineering. In mining, they are essential for drilling blast holes to break rock efficiently, allowing for the extraction of valuable resources. In the oil and gas sector, these bits are utilized for drilling exploratory and production wells, where precision and reliability are crucial.

In construction, carbide conical button bits are employed for various tasks, including foundation drilling and rock excavation. Their ability to tackle tough geological conditions makes them indispensable tools for engineers and contractors striving to complete projects on time and within budget.

Conclusion

As the demand for efficient and effective drilling solutions continues to grow, carbide conical button bits stand out as a key component in the rock drilling industry. Their innovative design, combined with the durability of tungsten carbide, ensures that they meet the high standards required for modern-day drilling operations. By investing in quality carbide conical button bits, operators can enhance their drilling performance, reduce downtime, and ultimately achieve greater success in their projects.

In summary, the carbide conical button bit is not just a tool; it represents a significant advancement in the field of rock drilling. Its unique design and high-performance characteristics make it an essential asset for any drilling operation, poised to meet the challenges of today and the future. As technology continues to evolve, the reliance on efficient and durable tools such as these will only increase, driving further innovation and productivity in the industry.