-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Chemical Solutions for FRP Applications A Complete Guide to Products and Techniques

Chemical Products for FRP Applications A Comprehensive Guide

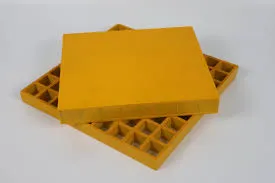

Fiber Reinforced Plastics (FRP) are materials composed of a polymer matrix reinforced with fibers, providing a unique combination of strength, lightweight properties, and corrosion resistance. These characteristics make FRP an ideal choice for a wide range of applications across various industries, including construction, automotive, aerospace, and marine. This article aims to provide a comprehensive guide to the chemical products used in FRP applications, focusing on resin systems, additives, and curing agents that enhance performance and tailor the material to specific requirements.

1. Resin Systems

The core of any FRP composite is the resin system, which binds the reinforcing fibers together. There are several types of resins commonly used in FRP applications

- Polyester Resins Unsaturated polyester resins are among the most commonly used materials in FRP composites. They offer a good balance of strength, flexibility, and chemical resistance. Polyester resins are cost-effective and can be easily molded into complex shapes, making them popular in industries such as marine, automotive, and construction.

- Vinyl Ester Resins Vinyl ester resins provide improved chemical resistance compared to standard polyester resins. They are ideal for applications requiring exposure to aggressive environments, such as chemical storage tanks and industrial structures. Their superior performance makes them slightly more expensive, yet they are highly valued for their durability.

- Epoxy Resins Epoxy resins are renowned for their exceptional mechanical properties and adhesion characteristics. They exhibit low shrinkage during curing and have excellent resistance to water, heat, and chemicals. Epoxy is particularly useful in demanding applications, including aerospace components and high-performance sporting goods.

2. Additives

To enhance the performance of FRP systems, various additives can be incorporated into the resin formulations. These include

- Fillers Fillers such as calcium carbonate, talc, and glass beads are added to resins to improve certain properties, like viscosity, thermal stability, and overall cost-effectiveness. Fillers can also help reduce the density of the final composite while maintaining its mechanical strength.

chemical products for frp applications a comprehensive guide ...

- Colorants Colorants and pigments can be added to resins to provide aesthetic appeal or to meet specific regulatory requirements. The choice of colorant can affect the curing process, so it’s essential to use compatible products.

- Fire Retardants In applications where fire resistance is critical, fire retardants can be incorporated into the resin formulation. These additives help to slow down combustion and can significantly increase the safety of the final product.

- Surface Modifiers Surface modifiers are used to improve the interaction between the resin and the reinforcing fibers, enhancing wet-out and adhesion. This results in improved mechanical properties and durability of the composite.

3. Curing Agents

Curing agents, or hardeners, play a vital role in the polymerization of resin systems. They initiate the chemical reaction that transforms liquid resins into solid composites. Common types of curing agents include

- Methyl Ethyl Ketone Peroxide (MEKP) MEKP is a widely used catalyst for polyester and vinyl ester resins. It promotes the curing process at room temperature but is sensitive to moisture and temperature variations.

- Amines Amine-based curing agents are used primarily with epoxy resins. They offer various curing times and flexibility, allowing manufacturers to customize the curing process according to their requirements.

- Anhydrides Anhydrides provide excellent adhesion and mechanical properties in curing epoxy resins. They offer extended working times, making them suitable for large-scale applications.

Conclusion

The versatile properties of Fiber Reinforced Plastics can be significantly enhanced through carefully selected chemical products. Understanding the different resin systems, additives, and curing agents available enables manufacturers to optimize their FRP composites for specific applications, ensuring superior performance and longevity. As technology advances and new formulations are developed, the potential of FRP materials continues to expand, promising exciting possibilities across various industries. By leveraging the right chemical products, businesses can meet the evolving demands of the market while achieving sustainability and efficiency.