-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

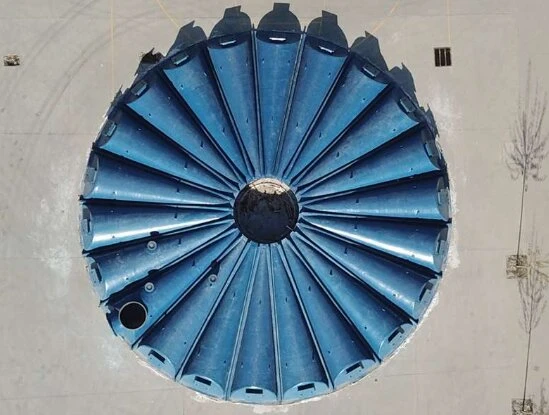

chemical storage tank

Understanding Chemical Storage Tanks Safety, Design, and Regulations

Chemical storage tanks are vital components in various industries, including pharmaceuticals, agriculture, and petrochemicals. They are essential for securely storing liquids and hazardous materials, complying with strict regulations while ensuring safety and efficiency. In this article, we will explore the significance of chemical storage tanks, their design considerations, safety features, and the regulations governing their use.

Importance of Chemical Storage Tanks

Chemical storage tanks serve numerous functions, primarily focusing on the safe and efficient containment of various liquids. These tanks protect the environment by preventing spills and leaks, thereby minimizing the risk to surrounding areas. Additionally, proper storage of chemicals can prolong their shelf life and maintain quality, which is particularly critical in the food and pharmaceutical industries.

Furthermore, strategically designed storage tanks can aid in managing inventory levels effectively, ensuring that businesses can operate without interruption. Efficient storage allows companies to have adequate supplies on hand, reducing the risk of production delays due to material shortages.

Design Considerations

When designing a chemical storage tank, several factors must be considered to ensure its effectiveness and safety. The tank's size, shape, and materials must correspond to the specific properties of the chemicals being stored. For instance, corrosive materials require tanks made of resistant materials such as stainless steel or fiberglass to prevent degradation over time.

Additionally, the design must incorporate adequate support structures to withstand the weight of the stored liquids and any environmental forces, such as wind or seismic activity. Engineers often conduct thorough risk assessments to identify potential hazards and tailor the design to mitigate them effectively.

Another crucial aspect to consider is temperature and pressure control. Some chemicals require specific storage conditions to maintain their stability. Therefore, it may be necessary to include heating or cooling systems, along with pressure relief valves, to maintain optimal environmental conditions within the tank.

Safety Features

chemical storage tank

The safety of chemical storage tanks is paramount, as the risks associated with storing hazardous materials can have catastrophic consequences. To enhance safety, these tanks often come equipped with various safety features.

One common feature is double-walled construction, which provides an additional layer of containment. This design ensures that, in the event of a leak in the inner tank, the outer wall acts as a secondary barrier, preventing the escape of hazardous materials into the environment.

Moreover, modern tanks are often outfitted with monitoring systems that detect leaks and other anomalies in real-time. These systems can include sensors for pressure, temperature, and chemical levels, enabling quick responses to any issues that may arise.

Adequate ventilation systems are also crucial in preventing the buildup of harmful vapors, which could pose health risks to workers and the surrounding community. Regular maintenance and inspections of these systems are vital to ensure their functionality and address any potential issues.

Regulatory Compliance

Chemical storage is subject to stringent regulations at both national and local levels. Agencies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) set forth guidelines to ensure the safe handling and storage of hazardous materials. Compliance with these regulations not only promotes safety but also helps organizations avoid costly fines and legal repercussions.

Companies must maintain detailed records of the chemicals stored, adhere to labeling requirements, and conduct regular training for employees on safety protocols. In many jurisdictions, businesses may be required to develop spill prevention, control, and countermeasure (SPCC) plans to mitigate risks associated with potential spills.

Conclusion

In conclusion, chemical storage tanks play a crucial role in the safe and efficient storage of hazardous materials across various industries. Proper design, robust safety features, and regulatory compliance are essential for minimizing risks and protecting both personnel and the environment. As industries evolve and new materials emerge, the importance of maintaining high standards in chemical storage will only continue to grow. Organizations must remain vigilant in their practices, ensuring that their storage solutions are secure, efficient, and compliant with existing regulations. By doing so, they contribute to a safer and environmentally responsible industrial landscape.