-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Combining Durability and Resistance in CPVC and FRP Pipe Systems for Enhanced Performance

Combining Durability and Resistance The Advantages of CPVC and FRP Pipes

In modern construction and industrial applications, the materials selected for piping systems play a crucial role in determining the longevity and reliability of any project. CPVC (Chlorinated Polyvinyl Chloride) and FRP (Fiberglass Reinforced Plastic) pipes have emerged as two of the most effective materials used in various sectors due to their unique properties of durability and resistance. This article explores the benefits of these materials and their combined advantages for contemporary piping needs.

Understanding CPVC Pipes

CPVC is a thermoplastic material characterized by its high resistance to temperature and pressure. It is created by chlorinating PVC, resulting in a product that can withstand higher temperatures compared to standard PVC. This feature makes CPVC pipes particularly beneficial for hot water transport applications, such as in residential plumbing and industrial processes. Furthermore, CPVC is resistant to corrosion, scaling, and the aggressive effects of harsh chemicals, making it suitable for various industrial applications, including chemical processing and wastewater treatment.

The lightweight nature of CPVC also contributes to its installation efficiency. Being easier to handle, cut, and join than traditional materials like metal, it reduces labor costs and installation time. Additionally, CPVC does not leach harmful substances, ensuring the safety of drinking water systems.

Exploring FRP Pipes

FRP pipes consist of a composite material made from a polymer matrix reinforced with fiberglass. This combination of materials provides FRP pipes with exceptional strength and versatility, making them a preferred choice in industries that require high-pressure systems, including oil and gas, wastewater treatment, and chemical processing.

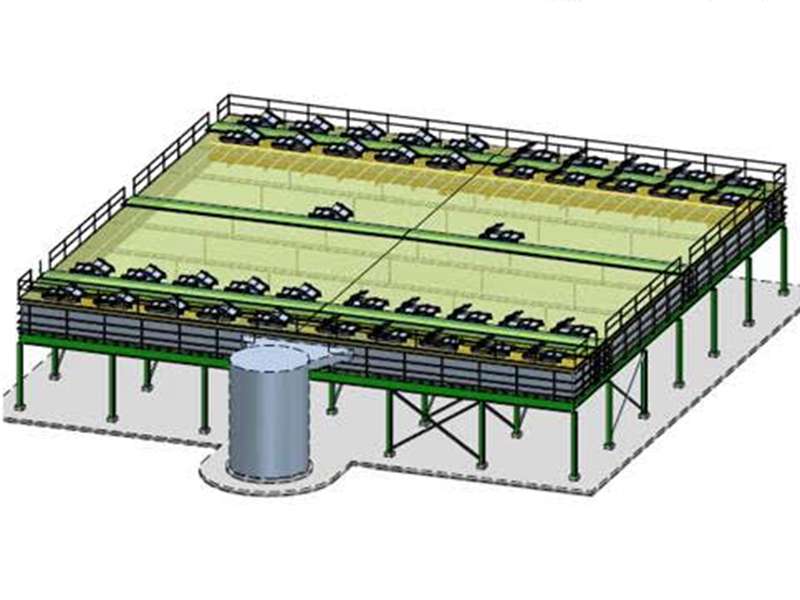

cpvc and frp pipes combine durability and resistance.

One of the standout properties of FRP is its superior corrosion resistance, which allows these pipes to perform well in harsh environments, including highly acidic or alkaline conditions. Moreover, FRP pipes are lightweight yet incredibly strong, which not only facilitates easy installation but also reduces the load on supporting structures.

FRP also offers excellent thermal insulation properties, which can enhance energy efficiency in transport systems. The ability to resist extreme temperatures without warping or deforming further extends the lifespan of FRP pipes, making them an ideal choice for a variety of applications.

The Synergy of CPVC and FRP

The combination of CPVC and FRP pipes harnesses the strengths of both materials, creating a pipeline system that excels in durability and resistance. For industries that demand both high temperature capability and formidable mechanical strength, the integration of these two materials can result in enhanced operational efficiency and safety.

For instance, in chemical processing plants, a piping system might involve the use of CPVC for transporting hot, corrosive liquids, while FRP pipes may be utilized in structural support and as conduits for other media. This synergistic approach not only maximizes performance but also helps in adhering to stringent safety and regulatory standards.

Conclusion

The evolving landscape of construction and industrial applications demands innovative solutions that guarantee both reliability and efficiency. CPVC and FRP pipes stand out for their exceptional durability and resistance to various damaging factors, making them prime candidates for modern piping systems. By combining the advantages of these two materials, industries can achieve safer, more efficient, and longer-lasting solutions for their fluid transport needs. As the demand for high-performance piping systems continues to grow, the integration of CPVC and FRP will undoubtedly play a critical role in shaping the future of piping technology.