-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

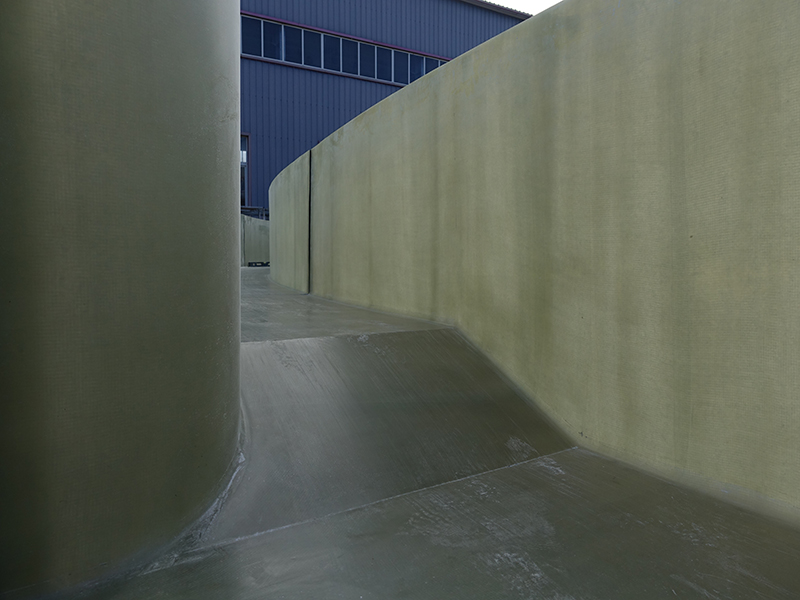

'corrosion-resistant fiberglass for enduring durability.'

Corrosion-Resistant Fiberglass A Solution for Enduring Durability

In today's commercial and industrial landscape, the need for materials that can withstand harsh environments has never been more pronounced. One material that has gained significant attention for its exceptional durability is corrosion-resistant fiberglass. This innovative composite material combines the lightweight properties of fiberglass with enhanced resilience against various corrosive agents, making it an ideal choice for a multitude of applications.

Fiberglass is composed of fine glass fibers that are woven together and bonded with a resin. The result is a sturdy material that is both lightweight and strong. However, when it comes to environments that expose materials to corrosive substances—such as chemicals, saltwater, and moisture—traditional fiberglass may not suffice. This is where corrosion-resistant fiberglass comes into play, equipped with specialized formulations that enhance its performance in the face of chemical hostility.

One of the key advantages of corrosion-resistant fiberglass is its ability to withstand aggressive chemicals. Industries such as chemical manufacturing, pharmaceuticals, and wastewater treatment heavily rely on materials that can resist not just surface-level degradation but also deeper chemical interactions. Corrosion-resistant fiberglass is engineered to offer an extended lifespan, reducing the need for frequent replacements and maintenance, which can be cost-prohibitive in the long run.

Moreover, corrosion-resistant fiberglass is exceptionally versatile. It can be tailored to meet specific operational requirements, such as varying temperatures and chemical exposures. For instance, in the oil and gas sector, fiberglass reinforced plastic (FRP) structures and components are used for pipes, tanks, and other essential systems. The resistance to various chemical attacks ensures that these components do not corrode over time, leading to safer and more reliable operations.

'corrosion-resistant fiberglass for enduring durability.'

In addition to its chemical resistance, fiberglass offers other inherent properties that contribute to its utility in demanding environments. It is non-conductive, making it a safe choice in electrical applications. This property is especially important for industries that require effective insulation from electric currents. Furthermore, fiberglass is lightweight, allowing for reduced transportation costs and easier installation without compromising structural integrity.

The sustainability factor also plays a significant role in the increasing preference for corrosion-resistant fiberglass. As industries globally push for eco-friendly alternatives, fiberglass provides a solution that aligns with these values. The manufacturing process of fiberglass can be optimized to reduce waste, and many formulations utilize recycled materials, making it a more sustainable choice than many traditional materials. Additionally, the longevity of fiberglass means that fewer materials need to be produced over time, further minimizing its environmental impact.

Safety is another critical aspect where corrosion-resistant fiberglass excels. In environments where traditional metals would corrode and pose safety hazards, fiberglass reduces the risk of structural failure. This is particularly crucial in the construction of bridges, marine structures, and industrial facilities. Using corrosion-resistant fiberglass not only guarantees structural integrity but also safeguards personnel who may be working in proximity to these materials.

Furthermore, the aesthetic flexibility of fiberglass cannot be overlooked. It can be produced in a variety of colors and finishes, allowing architects and designers to create visually appealing structures without sacrificing durability. This is especially important in public-facing structures where aesthetic considerations can significantly influence public perception and usability.

In conclusion, corrosion-resistant fiberglass stands out as a material of choice for enduring durability in challenging environments. Its unique combination of lightweight strength, chemical resistance, and sustainability makes it versatile across a range of applications, from industrial settings to architectural projects. As industries continue to evolve and face greater demands for robust materials, the adoption of corrosion-resistant fiberglass is likely to expand. Manufacturers, engineers, and environmental advocates will continue to benefit from innovations in composite materials, paving the way for safer, more sustainable practices in construction and beyond. Embracing corrosion-resistant fiberglass is not just a step toward durability, but a stride towards a more resilient and sustainable future in material science.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025