-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

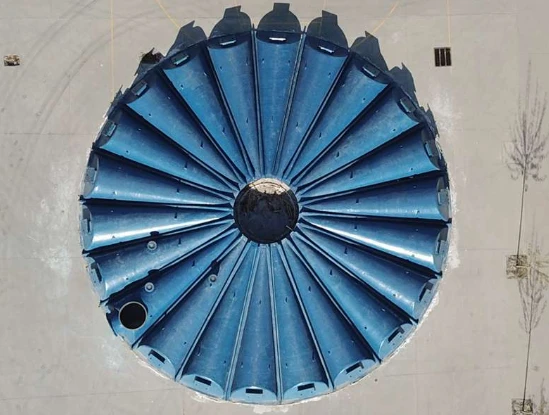

Durable Corrosion-Resistant Fiberglass for Long-Lasting Performance and Reliability

The Advantages of Corrosion-Resistant Fiberglass for Enduring Durability

In an era where material science continuously evolves to meet the demanding challenges of various industries, corrosion-resistant fiberglass stands out as a superior choice for applications requiring long-lasting durability. This innovative material combines strength, lightweight properties, and unmatched resistance to corrosion, making it a vital asset in sectors such as construction, marine, chemical processing, and even aerospace.

Understanding Corrosion-Resistant Fiberglass

Corrosion is a natural process that deteriorates materials over time, especially metals, through chemical reactions with environmental factors. Industries that rely on metal components often grapple with this persistent issue, incurring significant costs for maintenance and replacement. Corrosion-resistant fiberglass, however, provides a solution. This composite material is typically made from glass fibers embedded in a resin matrix, which not only provides structural integrity but also enhances resistance to corrosive agents.

The two primary types of resin used in the production of fiberglass are polyester and epoxy. Polyester resin offers a cost-effective solution, ideal for applications where chemical exposure is limited. On the other hand, epoxy resin offers superior protection against a wider range of chemicals and is resistant to high temperatures, making it suitable for more demanding environments.

Advantages of Corrosion-Resistant Fiberglass

1. Exceptional Durability

One of the most significant benefits of corrosion-resistant fiberglass is its remarkable durability. Unlike traditional materials like steel or aluminum, fiberglass does not rust or corrode when exposed to moisture or aggressive chemicals. This durability translates into a longer lifespan for components, reducing the need for frequent replacements and repairs—an attractive proposition for businesses looking to minimize downtime and costs.

2. Lightweight and Strong

Corrosion-resistant fiberglass is notably lighter than many metals, providing a major advantage in applications where weight is a critical factor. For instance, in the aerospace industry, reducing weight contributes to improved fuel efficiency and performance. In construction and shipbuilding, lighter materials ease handling and reduce overall structural load, allowing for versatile design solutions.

'corrosion-resistant fiberglass for enduring durability.'

3. Cost-Effectiveness

Although the initial investment in corrosion-resistant fiberglass may be higher than conventional materials, the long-term cost savings are significant. Reduced maintenance, increased replacement cycles, and minimal downtime directly translate into lower operating costs. Moreover, the longevity of fiberglass components can significantly outweigh the initial expenditure, making it a smart financial choice.

4. Versatile Applications

Corrosion-resistant fiberglass is incredibly versatile, making it suitable for various sectors. In the chemical industry, it is used for storage tanks, piping, and containment vessels due to its ability to resist aggressive chemicals. In the construction sector, it serves as an excellent material for building facades, bridge components, and structural reinforcements. In marine applications, fiberglass hulls are preferred for boats since they can withstand harsh saltwater conditions without degrading.

5. Environmental Benefits

In today’s environmentally conscious world, the use of corrosion-resistant fiberglass can also be seen as a sustainable option. Its durability means that fewer materials need to be produced and disposed of, resulting in less waste and resource consumption over time. Additionally, many fiberglass formulations are designed to be recyclable, contributing to a circular economy.

6. Aesthetic Flexibility

Fiberglass can be molded into a wide variety of shapes and sizes, allowing for creative and aesthetically pleasing designs. It can also be finished in virtually any color, providing design flexibility that is often not achievable with metals. This makes it a popular choice for industries that value both functionality and aesthetics, such as architecture and product design.

Conclusion

Corrosion-resistant fiberglass is paving the way for advancements in material technology by providing solutions that address the challenges of corrosion and degradation. With its exceptional durability, lightweight properties, cost-effectiveness, and versatility, it has become an essential material across multiple industries. As innovation continues to evolve, the applications for this remarkable material are likely to expand even further, solidifying its importance in the modern world. Embracing corrosion-resistant fiberglass means investing in a durable future, where longevity and performance go hand in hand.