-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 05, 2025 02:44

Back to list

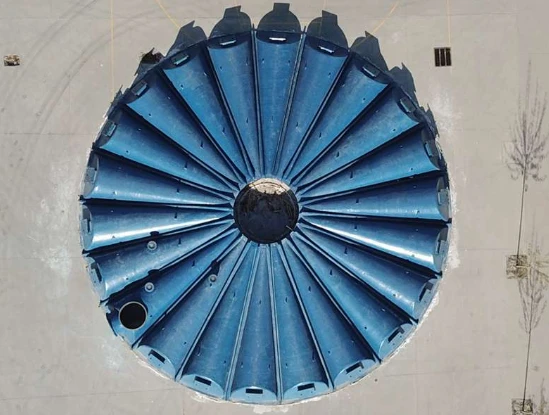

corrosion resistant fiberglass

Corrosion resistance is an essential attribute in many industries where long-term durability and reduced maintenance are required. Fiberglass has emerged as a leading material in this regard, thanks to its superior qualities that align with the growing demand for sustainable solutions. From water treatment plants to chemical processing facilities, the demand for corrosion-resistant fiberglass is ever-increasing, offering unparalleled solutions for industrial challenges.

Authoritativeness is another cornerstone when considering materials for construction and manufacturing. Leading fiberglass manufacturers leverage decades of research and empirical data to refine their products. Independent studies and certifications from industry bodies often back the claims for fiberglass, adding layers of credibility. For businesses and engineers who require assurance beyond anecdotal evidence, these certifications provide a verified endorsement of fiberglass' performance in corrosion-prone environments. Trustworthiness is essential when businesses decide to invest in new materials, where an incorrect choice could lead to continuous operational setbacks. Fiberglass, with its proven track record, often exceeds the lifecycle of traditional alternatives like steel or aluminum when used in corrosive settings. Its inertness and ability to remain unaffected by extreme temperatures and chemicals enhance its reliability. This attribute becomes increasingly vital when structures are remote, hard to access, or critical to infrastructure, where regular maintenance is impractical or costly. Furthermore, ongoing innovation in fiberglass technology continually expands its utility and confirms its trustworthiness. Developments such as UV-resistant coatings, enhanced resins that expand the range of tolerable chemical exposures, and thermal bridges that reduce energy loss all stem from established professionals actively engaged in pushing the boundaries of fiberglass capabilities. In summary, the advantages of corrosion-resistant fiberglass are evident through its real-world applications and robust, expert-backed composition. Its ability to provide a high degree of expertise, authority, and trustworthiness makes it an indispensable material across industries seeking durable, maintenance-free solutions in corrosive environments. As more data emerges and technology advances, fiberglass is set to reinforce its position as a material that not only meets but exceeds industrial expectations.

Authoritativeness is another cornerstone when considering materials for construction and manufacturing. Leading fiberglass manufacturers leverage decades of research and empirical data to refine their products. Independent studies and certifications from industry bodies often back the claims for fiberglass, adding layers of credibility. For businesses and engineers who require assurance beyond anecdotal evidence, these certifications provide a verified endorsement of fiberglass' performance in corrosion-prone environments. Trustworthiness is essential when businesses decide to invest in new materials, where an incorrect choice could lead to continuous operational setbacks. Fiberglass, with its proven track record, often exceeds the lifecycle of traditional alternatives like steel or aluminum when used in corrosive settings. Its inertness and ability to remain unaffected by extreme temperatures and chemicals enhance its reliability. This attribute becomes increasingly vital when structures are remote, hard to access, or critical to infrastructure, where regular maintenance is impractical or costly. Furthermore, ongoing innovation in fiberglass technology continually expands its utility and confirms its trustworthiness. Developments such as UV-resistant coatings, enhanced resins that expand the range of tolerable chemical exposures, and thermal bridges that reduce energy loss all stem from established professionals actively engaged in pushing the boundaries of fiberglass capabilities. In summary, the advantages of corrosion-resistant fiberglass are evident through its real-world applications and robust, expert-backed composition. Its ability to provide a high degree of expertise, authority, and trustworthiness makes it an indispensable material across industries seeking durable, maintenance-free solutions in corrosive environments. As more data emerges and technology advances, fiberglass is set to reinforce its position as a material that not only meets but exceeds industrial expectations.

Next:

Related Products