-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

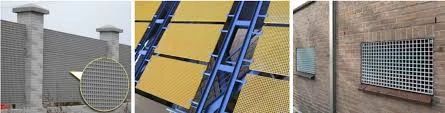

corrosion resistant frp

The Advantages of Corrosion-Resistant FRP in Industrial Applications

Corrosion is a significant concern in many industrial applications, particularly in environments where exposure to chemicals, moisture, and varying temperatures is commonplace. Traditional materials like steel often succumb to corrosion, leading to decreased lifespan, increased maintenance costs, and potential safety hazards. This is where corrosion-resistant Fiber Reinforced Plastic (FRP) materials come into play, offering a durable and cost-effective alternative.

FRP is a composite material made by combining a polymer matrix, usually thermosetting resins like epoxy or polyester, with reinforcing fibers such as glass, carbon, or aramid. This combination results in a lightweight material that possesses exceptional strength and resilience. One of the most compelling features of FRP is its corrosion resistance, making it ideal for various industrial applications.

Key Benefits of Corrosion-Resistant FRP

1. Durability and Longevity FRP materials are highly resistant to a range of corrosive substances, including acids, alkalis, and salts. This resistance significantly extends the lifespan of components made from FRP, reducing the need for frequent replacements and repairs.

2. Lightweight Nature Compared to metals, FRP is considerably lighter, making it easier to handle, transport, and install. This lightweight characteristic can lead to lower overall structural costs and reduced labor expenses during installation.

3. Low Maintenance Requirements The inherent resistance of FRP to corrosion reduces the need for routine maintenance and inspections. Industries can save significant amounts of money by minimizing downtime and maintenance activities traditionally associated with metal components.

4. Versatility in Design FRP can be molded into various shapes and sizes, providing flexibility in design that traditional materials may not offer. This versatility allows engineers and designers to create customized solutions that meet specific application requirements, leading to enhanced performance and efficiency.

corrosion resistant frp

5. Thermal and Electrical Insulation In addition to its corrosion resistance, FRP is an excellent insulator of heat and electricity. This quality makes it suitable for applications where thermal and electrical conductivity must be minimized, such as in piping systems and support structures.

6. Environmental Resistance FRP materials are also resistant to UV radiation, making them ideal for outdoor applications. They do not degrade when exposed to sunlight, ensuring long-lasting performance in various environmental conditions.

Applications in Various Industries

Corrosion-resistant FRP is increasingly being adopted across a wide range of industries. In the chemical processing sector, FRP is used for storage tanks, piping, and protective linings, providing reliable solutions for handling corrosive substances. The marine industry also benefits from FRP, utilizing it in boat hulls, dock components, and underwater equipment where saltwater exposure can lead to rapid corrosion of metals.

Additionally, the oil and gas industry employs FRP for components exposed to harsh chemicals and extreme conditions. Water treatment facilities use FRP for tanks and piping systems that need to withstand both mechanical stress and aggressive media without corroding.

Conclusion

The adoption of corrosion-resistant FRP materials presents a significant opportunity for industries grappling with the challenges of corrosion. With benefits such as durability, low maintenance, lightweight properties, and design versatility, FRP stands out as a superior alternative to traditional materials. As industries continue to seek innovative solutions to enhance productivity and reduce costs, the use of FRP is expected to grow, shaping the future of material engineering and industrial applications.