-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

corrosion solution

Understanding Corrosion and Its Solutions

Corrosion is a natural process that involves the gradual destruction of materials, usually metals, due to chemical reactions with their environment. It is a widespread issue that affects various sectors, including construction, manufacturing, transportation, and many others. Understanding corrosion and implementing effective solutions is crucial for maintaining the integrity of structures and machinery, thus preventing costly repairs and ensuring safety.

What Causes Corrosion?

Corrosion occurs when metals react with moisture, oxygen, and other environmental factors, leading to deterioration. The most common form of corrosion is rusting, which happens when iron or steel reacts with oxygen in the presence of water or moisture, resulting in iron oxide. However, other metals like copper, aluminum, and zinc also corrode, though the processes and resulting compounds vary.

Several factors can accelerate corrosion, including

1. Environmental Conditions High humidity, saltwater exposure, and acidic or alkaline environments can significantly increase corrosion rates. 2. Electrochemical Factors The presence of certain electrolytes can enhance the conductivity of moisture, facilitating the flow of electric current, which accelerates the corrosion process. 3. Material Composition Different metals have varying resistance to corrosion based on their chemical properties. For instance, stainless steel, which contains chromium, is less prone to corrosion than regular steel.

Types of Corrosion

Corrosion can manifest in several forms, such as

- Uniform Corrosion Occurs evenly across a surface, leading to a gradual loss of material. It is the most predictable and, often, the easiest to manage. - Pitting Corrosion Characterized by small, localized areas of corrosion that can lead to significant damage over time, pitting is often challenging to detect until severe damage has occurred. - Galvanic Corrosion This occurs when two dissimilar metals are in contact in the presence of an electrolyte, leading to one metal corroding preferentially over the other. - Crevice Corrosion Found in confined spaces or crevices, this type of corrosion is exacerbated by a lack of oxygen, which creates an environment conducive to corrosion.

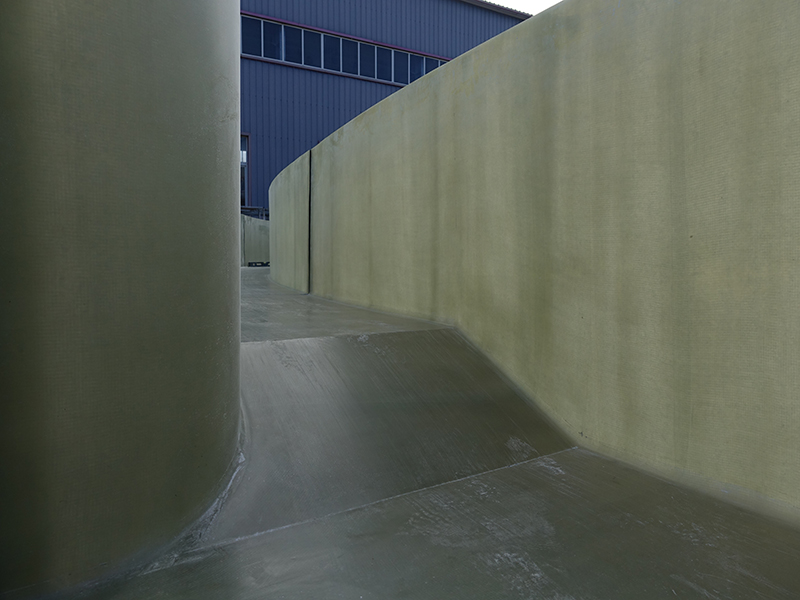

corrosion solution

Methods of Corrosion Prevention

Preventing corrosion is essential for ensuring the longevity and reliability of metal structures. Several methods can be employed to minimize the risk of corrosion

1. Protective Coatings Applying paints, varnishes, or galvanization can create a barrier between the metal and corrosive elements. Coatings can be an effective first line of defense against corrosion.

2. Corrosion Inhibitors These are chemicals that can be added to the environment to slow down the corrosion process. They can be particularly useful in liquid systems like cooling towers and pipelines.

3. Cathodic Protection This technique involves making the metal structure the cathode of an electrochemical cell, thus preventing oxidation. It is commonly used for underground pipelines and storage tanks.

4. Material Selection Choosing corrosion-resistant materials for construction and manufacturing can significantly reduce the likelihood of corrosion. For instance, using stainless steel or aluminum instead of regular steel can enhance durability.

5. Regular Inspection and Maintenance Routine checks can help identify early signs of corrosion, allowing for timely repair or preventive measures. Maintenance practices such as cleaning and touch-up painting can extend the life of structures.

Conclusion

Corrosion is an unavoidable process that can lead to severe consequences if not properly addressed. By understanding the factors that contribute to corrosion and implementing effective prevention methods, industries can mitigate risks and prolong the lifespan of their assets. A proactive approach, involving the use of protective coatings, corrosion inhibitors, cathodic protection, strategic material selection, and consistent maintenance, can significantly reduce the impact of corrosion on metals. As technology continues to evolve, new innovations in corrosion prevention and monitoring will provide even more effective solutions for safeguarding metals and ensuring structural integrity.