-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring Effective Solutions for Corrosion Prevention and Management in Various Industries

Understanding Corrosion Causes, Effects, and Solutions

Corrosion is a natural process that leads to the deterioration of materials, primarily metals, due to chemical reactions with their environment. This phenomenon has significant implications across various industries, from construction to automotive and electronics, making it a critical consideration for engineers, manufacturers, and environmental scientists alike. Understanding the causes of corrosion, its effects, and the available solutions is essential for mitigating its impact on both infrastructure and the economy.

Causes of Corrosion

Corrosion is predominantly an electrochemical process, involving the oxidation of metals. Several factors contribute to this process, including moisture, temperature, pH levels, and the presence of salts or other corrosive agents. For instance, in a wet environment, iron reacts with oxygen and water to form iron oxide, commonly known as rust. This reaction is accelerated in the presence of salt, making coastal areas particularly susceptible to corrosion due to sea spray.

Different types of corrosion exist, including uniform corrosion, pitting, galvanic corrosion, and intergranular corrosion. Uniform corrosion occurs uniformly across the surface of a metal, while pitting involves localized corrosion resulting in small cavities or pits. Galvanic corrosion happens when two dissimilar metals are in contact in the presence of an electrolyte, leading to accelerated degradation of one of the metals. Intergranular corrosion affects the grain boundaries of a metal, weakening its structure over time.

Effects of Corrosion

The effects of corrosion can be extensive and often costly. In infrastructure, corrosion can lead to structural failures, which pose risks to safety and can incur significant repair or replacement costs. For example, corroded steel reinforcements in concrete can compromise the integrity of bridges and buildings. In the automotive industry, corrosion can reduce the lifespan of vehicles and increase maintenance costs. Electronics can also suffer, as corrosion may affect circuit boards and connectors, leading to malfunctions.

The economic impact of corrosion is staggering; it is estimated that corrosion costs the global economy trillions of dollars annually. This includes direct costs, such as repairs and replacements, as well as indirect costs, such as loss of productivity and safety hazards. Additionally, corrosion can have environmental implications, releasing toxic substances into the surrounding ecosystem when materials degrade.

Solutions to Corrosion

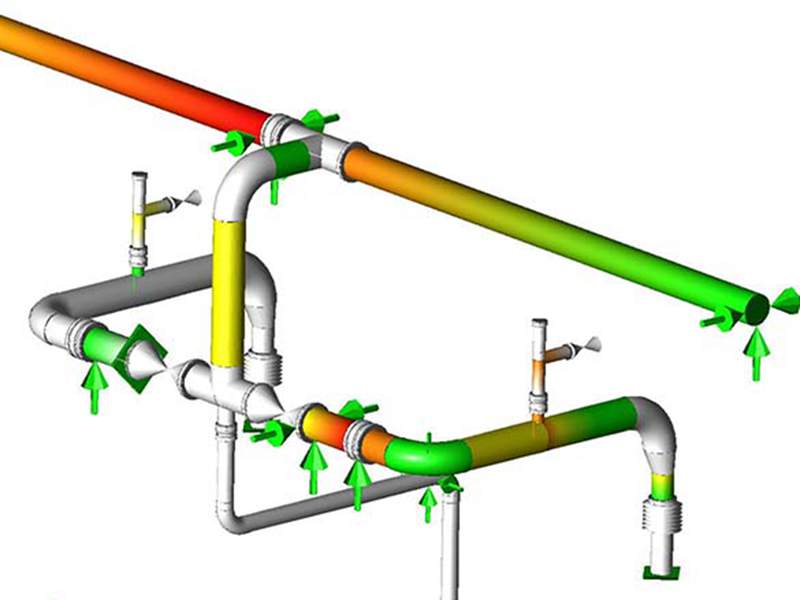

corrosion solution

Given the significant impact of corrosion, various solutions have been developed to combat this issue. These can be categorized into preventive measures, protective coatings, and materials selection.

1. Preventive Measures Regular inspections and maintenance of structures can help identify early signs of corrosion. Implementing proper drainage systems and controlling environmental factors can also reduce the risk of corrosion in susceptible areas.

2. Protective Coatings Coatings such as paints, galvanization, or powder coatings are applied to metal surfaces to create a barrier between the metal and the environment. For example, galvanizing involves coating steel with a layer of zinc, which protects the underlying metal from corrosion. Other coatings, like epoxy resins, provide a robust protective layer, particularly in industrial applications.

3. Corrosion Inhibitors These are chemical compounds that, when added to a corrosive environment, decrease the rate of corrosion. Corrosion inhibitors work by forming a protective layer on the metal surface or by neutralizing corrosive agents in the environment. They are frequently used in pipelines and boilers to extend their lifespan.

4. Material Selection Choosing the right materials for specific environments is crucial in corrosion prevention. Stainless steel, for instance, contains chromium, which provides a protective oxide layer, making it more resistant to corrosion, especially in moisture-rich environments.

5. Cathodic Protection This method involves applying a small electrical current to the metal, making it the cathode in an electrochemical cell. It is commonly used to protect pipelines and storage tanks from corrosion.

Conclusion

Corrosion is an inevitable process that can have severe consequences if not adequately managed. Understanding its causes and effects allows industries to implement effective solutions to mitigate its impact. Through preventive measures, protective coatings, the use of corrosion inhibitors, careful material selection, and techniques like cathodic protection, we can significantly reduce the challenges posed by corrosion. Continuing research and innovation in this field will be crucial for developing more effective strategies to protect our essential infrastructure and reduce economic losses caused by this pervasive problem. As we progress further into the 21st century, addressing corrosion will remain a priority for ensuring safety, sustainability, and economic resilience.