-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

CPVC FRP Pipe | High-Quality CPVC Fiber Reinforced Plastic Pipe Solutions

Understanding CPVC and FRP Pipes A Comprehensive Overview

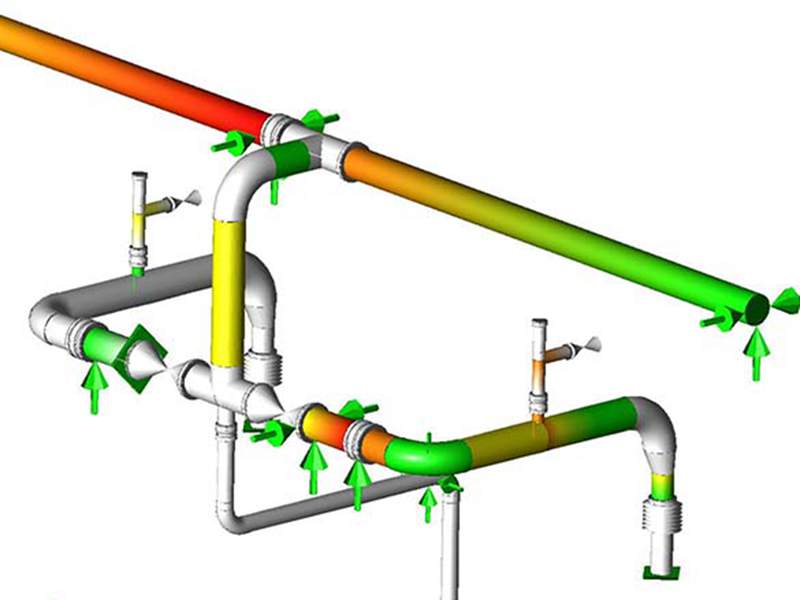

In the world of piping systems, the choice of material often determines the efficiency, longevity, and overall performance of an installation. Two notable materials that have gained popularity are Chlorinated Polyvinyl Chloride (CPVC) and Fiberglass Reinforced Plastic (FRP). Each of these materials has unique characteristics that make them suitable for specific applications, contributing to their rising prevalence in various industries.

CPVC Pipes Properties and Applications

CPVC is a thermoplastic material derived from PVC, with chlorine added to enhance stability and heat resistance. This innovation allows CPVC pipes to withstand higher temperatures, typically up to 200°F (93°C), making them ideal for hot water applications. One of the main advantages of CPVC pipes is their resistance to corrosion and scale build-up, which are common issues in metal piping systems. This property ensures a longer lifespan and reduced maintenance costs, making CPVC a cost-effective choice for residential and commercial plumbing, industrial piping, and fire protection systems.

Additionally, CPVC pipes are lightweight and easy to handle, allowing for simpler installation processes. They can be bonded using specific solvents, creating a strong, leak-proof connection. This versatility extends CPVC’s applications further into HVAC systems, chemical manufacturing, and potable water supply.

FRP Pipes Strength and Durability

On the other hand, Fiberglass Reinforced Plastic (FRP) pipes combine plastic and glass fibers to create a composite material that is impressively strong yet lightweight. The unique manufacturing process provides FRP pipes with exceptional resistance to chemicals and corrosive environments, making them ideal for industries dealing with aggressive substances, such as wastewater treatment plants, oil and gas sectors, and chemical processing facilities.

cpvc frp pipe

FRP pipes exhibit high structural integrity and can endure extreme temperatures, ranging from -30°F to 200°F (-34°C to 93°C), depending on the specific resin used. Their flexibility allows them to accommodate expansion and contraction without sacrificing performance. Furthermore, FRP systems can be designed to meet high-pressure specifications, providing additional safety and reliability in demanding environments.

Comparing CPVC and FRP Pipes

When comparing CPVC and FRP pipes, one must consider the specific requirements of a project. CPVC is often preferred for residential plumbing and low-temperature applications due to its ease of installation and cost-effectiveness. In contrast, FRP pipes are better suited for harsh environments where chemical resistance and pressure tolerance are essential.

Both materials boast significant advantages over traditional metal pipes, including reduced weight, lower corrosion rates, and ease of installation. However, the initial cost may vary, with FRP generally being more expensive due to its complex manufacturing process.

Conclusion

In conclusion, the choice between CPVC and FRP pipes depends largely on the specific application and the environmental conditions they will face. Understanding the properties and benefits of each material allows engineers and project managers to make informed decisions, ultimately leading to enhanced efficiency and reliability in piping systems. As industries continue to evolve, the demand for these advanced piping solutions is expected to grow, further solidifying their role in modern infrastructure and construction.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025