-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

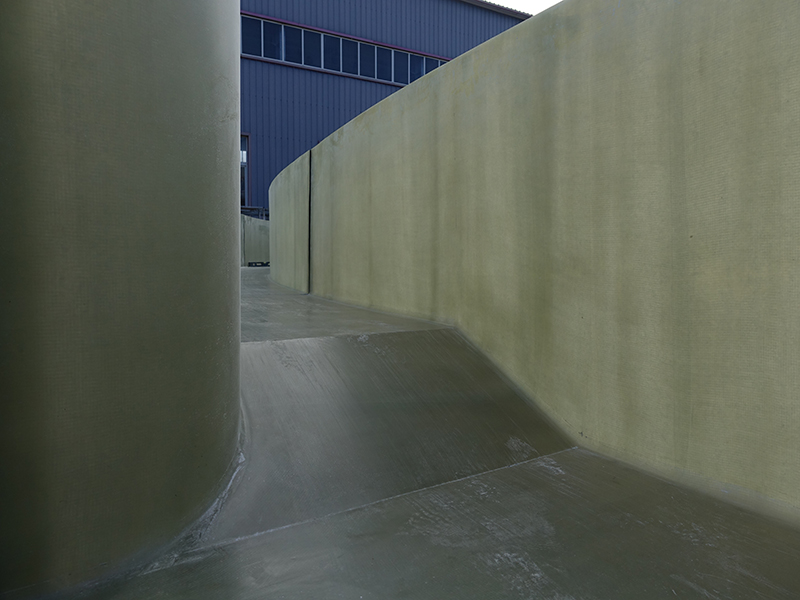

Combining Durability and Resistance of CPVC and FRP Pipes for Optimal Performance

Combining Durability and Resistance The Role of CPVC and FRP Pipes in Modern Infrastructure

In the ever-evolving landscape of industrial and infrastructural applications, the choice of materials plays a pivotal role in determining the longevity, efficiency, and overall performance of systems. Two materials that have garnered significant attention in recent years are Chlorinated Polyvinyl Chloride (CPVC) and Fiber Reinforced Plastic (FRP). Each material offers distinct advantages, and when combined, they enhance the capabilities of piping systems, making them a preferred choice in industries ranging from construction to chemical processing.

Understanding the Materials

CPVC is a thermoplastic material known for its toughness and high resistance to heat and corrosion. Its unique chemical structure allows it to withstand temperatures above those of standard PVC, making it an ideal candidate for hot water heating systems and various chemical applications. The material’s smooth surface reduces friction, ensuring efficient fluid flow and minimizing the risk of bacterial growth, which is particularly important in potable water systems.

On the other hand, FRP is a composite material made by combining a polymer matrix (usually plastic) with reinforcing fibers, such as glass, carbon, or aramid. This combination results in a lightweight material that exhibits exceptional strength and durability under a variety of environmental conditions. FRP pipes resist corrosion, making them suitable for use in aggressive chemical environments. They also demonstrate excellent dimensional stability and can withstand significant pressure without compromising integrity.

Advantages of Combining CPVC and FRP

The combination of CPVC and FRP results in a piping system that effectively harnesses the strengths of both materials

. Here are some of the key benefits1. Enhanced Corrosion Resistance One of the most significant challenges in piping systems is corrosion, which can lead to leaks, system failures, and costly repairs. CPVC pipes inherently resist corrosion from various chemicals and water, while FRP offers outstanding resistance to a wide range of aggressive substances. Together, they form a system that is exceptionally resistant to corrosive environments.

cpvc and frp pipes combine durability and resistance.

2. Improved Thermal Performance CPVC’s ability to handle high temperatures complements FRP's thermal stability. This combination allows the piping system to efficiently transport hot fluids without the risk of deformation or failure. Industries that rely on thermal processes, such as power generation and manufacturing, benefit immensely from this durability.

3. Weight and Flexibility FRP is significantly lighter than traditional materials like metal, which reduces the overall weight of the piping system. This quality not only simplifies installation but also lowers transportation costs. The flexibility of both materials allows for easier handling and conformity to various design requirements.

4. Longevity and Reduced Maintenance The durability of both CPVC and FRP means that piping systems can operate effectively over extended periods without the need for frequent maintenance or replacement. This longevity translates to lower lifecycle costs and less disruption to operations.

5. Environmental Resistance Both CPVC and FRP are designed to withstand extreme environmental conditions, including temperature fluctuations, UV exposure, and moisture. This resistance makes them ideal candidates for outdoor applications or in harsh industrial environments.

6. Cost-Effectiveness While the initial investment in CPVC and FRP piping systems may be higher than traditional materials, the long-term savings related to durability, reduced maintenance, and replacement costs make them an economically viable choice.

Conclusion

As industries continue to seek out innovative and sustainable solutions, the combination of CPVC and FRP pipes stands out as a revolutionary advancement in piping technology. Their collective durability and resistance properties not only enhance the efficiency and reliability of piping systems but also contribute to more sustainable practices in infrastructure development. By investing in these advanced materials, industries can ensure safer, more efficient operations while minimizing their environmental footprint. As we move towards a future that demands resilience and adaptability, the role of CPVC and FRP will undoubtedly remain central to modern infrastructural solutions.