-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 19, 2025 00:42

Back to list

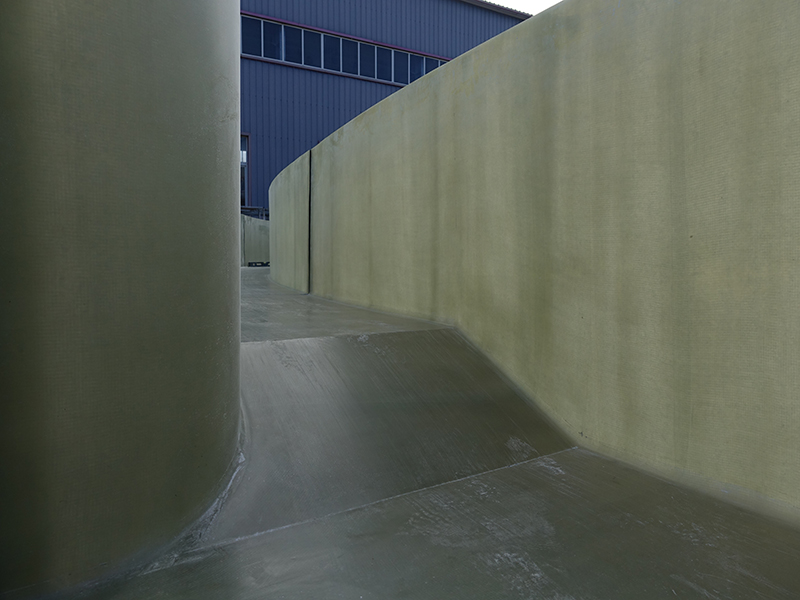

cpvc and frp pipes combine durability and resistance.

Combining CPVC and FRP pipes can revolutionize industrial applications where durability and resistance to corrosive environments are paramount. Through expert insights and real-world experiences, this article delves into the advantages, applications, and reliability of using CPVC and FRP pipes for enduring industrial challenges.

Practical applications illustrate the success of CPVC and FRP pipe systems. In power generation plants, where cooling water systems are routinely exposed to aggressive chemicals and thermal fluctuations, CPVC/FRP piping has demonstrated unwavering performance. Real-world case studies show that these piping systems can reduce maintenance shutdowns while providing continuous, reliable operation in environments demanding robust materials. Furthermore, the combination of CPVC and FRP in pipes ensures compliance with stringent safety and environmental standards. Each material's compliance with international certifications for safety and quality underscores their credibility, ensuring users can trust these pipes under challenging conditions. This trusted compliance reassures industries aiming to improve their environmental footprint without compromising performance. Authoritative voices within the piping industry emphasize the necessity of using certified composite materials for rigorous applications. Professionals advocate for regulatory adherence not just to meet legal standards but to exceed clients' expectations for safety and reliable service delivery. Moreover, anecdotal evidence from engineers and plant operators supports the notion that CPVC and FRP hybrid pipes offer unmatched peace of mind, due to their proven track record in hostile environments. Ultimately, CPVC and FRP composite piping systems provide industries with a path to achieving superior fluid handling solutions. Their durable, corrosion-resistant nature coupled with cost-effectiveness positions them as the piping materials of choice for future-ready infrastructures. As industries lean towards more sustainable and resilient technologies, the unique combination of CPVC and FRP stands as a testament to innovation meeting necessity in materials engineering. Consideration of these factors—based on expert endorsement, practical success stories, authoritative insights, and trust in material compliance—reveals the substantial benefits of integrating CPVC and FRP pipes within industrial realms. As industries continue to advance, embracing such robust solutions ensures long-term efficiency, safety, and reliability in even the most demanding applications.

Practical applications illustrate the success of CPVC and FRP pipe systems. In power generation plants, where cooling water systems are routinely exposed to aggressive chemicals and thermal fluctuations, CPVC/FRP piping has demonstrated unwavering performance. Real-world case studies show that these piping systems can reduce maintenance shutdowns while providing continuous, reliable operation in environments demanding robust materials. Furthermore, the combination of CPVC and FRP in pipes ensures compliance with stringent safety and environmental standards. Each material's compliance with international certifications for safety and quality underscores their credibility, ensuring users can trust these pipes under challenging conditions. This trusted compliance reassures industries aiming to improve their environmental footprint without compromising performance. Authoritative voices within the piping industry emphasize the necessity of using certified composite materials for rigorous applications. Professionals advocate for regulatory adherence not just to meet legal standards but to exceed clients' expectations for safety and reliable service delivery. Moreover, anecdotal evidence from engineers and plant operators supports the notion that CPVC and FRP hybrid pipes offer unmatched peace of mind, due to their proven track record in hostile environments. Ultimately, CPVC and FRP composite piping systems provide industries with a path to achieving superior fluid handling solutions. Their durable, corrosion-resistant nature coupled with cost-effectiveness positions them as the piping materials of choice for future-ready infrastructures. As industries lean towards more sustainable and resilient technologies, the unique combination of CPVC and FRP stands as a testament to innovation meeting necessity in materials engineering. Consideration of these factors—based on expert endorsement, practical success stories, authoritative insights, and trust in material compliance—reveals the substantial benefits of integrating CPVC and FRP pipes within industrial realms. As industries continue to advance, embracing such robust solutions ensures long-term efficiency, safety, and reliability in even the most demanding applications.

Related Products