-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Choosing CPVC FRP Pipes for Dependable Industrial Use in Various Applications

CPVC FRP Pipe A Reliable Choice for Industrial Applications

In the realm of industrial applications, the materials used for piping systems play a crucial role in ensuring efficiency, safety, and longevity. One such innovative solution that has garnered attention is the combination of Chlorinated Polyvinyl Chloride (CPVC) and Fiber Reinforced Plastic (FRP) pipes. This article delves into the advantages and applications of CPVC FRP pipes, making a compelling case for their use in various industries.

Understanding CPVC and FRP

Before discussing the advantages of CPVC FRP pipes, it is vital to understand the properties of the components involved. CPVC is a thermoplastic produced by chlorinating PVC resin. It possesses enhanced temperature resistance and chemical stability compared to regular PVC, making it ideal for applications where moderate temperature and high-pressure handling are required.

FRP, on the other hand, is a composite material consisting of a polymer matrix reinforced with fibers. The most common fibers used are glass, carbon, and aramid, which significantly enhance the mechanical properties of the plastic. When combined, CPVC and FRP offer a piping solution that can stand up to the rigors of industrial applications.

Advantages of CPVC FRP Pipes

1. Chemical Resistance One of the standout features of CPVC FRP pipes is their remarkable resistance to a wide range of chemicals. Industries such as chemical manufacturing, pharmaceuticals, and wastewater treatment require pipes that can handle corrosive substances without degrading. CPVC FRP pipes effectively resist acids, bases, and salts, ensuring longevity and reliability.

2. Temperature Tolerance CPVC can withstand higher temperatures than standard PVC, making it suitable for hot water transport and various industrial processes. The incorporation of FRP further enhances this property. Together, they can perform optimally in temperatures ranging from below zero to over 200°F (93°C).

3. Lightweight yet Strong The lightweight nature of CPVC FRP pipes offers significant advantages in terms of installation and transportation. Traditional metal pipes can be cumbersome and require extensive support structures. In contrast, these composite pipes allow for easier handling while still providing exceptional strength and durability.

4. Low Thermal Conductivity The thermal insulation properties of CPVC FRP pipes reduce energy loss and contribute to maintaining the desired temperature in systems that transport hot or cold fluids. This insulation capability can lead to reduced energy costs and enhanced safety in industrial applications.

cpvc frp pipe a reliable choice for industrial applications ...

5. Environmental Impact As industries increasingly focus on sustainability, the environmental advantages of CPVC FRP pipes cannot be overlooked. These pipes are recyclable and contribute to lower carbon emissions during production compared to metal alternatives.

6. Maintenance and Longevity The smooth internal surface of CPVC FRP pipes minimizes friction, reducing wear and tear over time, which translates to lower maintenance costs. Their resistance to corrosion and scaling outlasts many traditional materials, resulting in a long service life, sometimes exceeding 50 years under proper conditions.

Applications in Various Industries

Due to their unique properties, CPVC FRP pipes find applications across a spectrum of industries

- Chemical Processing The ability to resist corrosive substances makes these pipes ideal for transporting acids and other chemicals used in manufacturing processes. - Water and Wastewater Treatment The resistance to biofouling and corrosion helps ensure reliable performance in treatment plants, contributing to environmental protection and human health.

- Power Generation In power plants, CPVC FRP pipes are utilized in cooling water systems and chemical dosing applications due to their thermal and chemical resistance.

- Oil and Gas Industry They can be used in various upstream and downstream processes, including transportation of crude oil, natural gas, and related chemicals.

Conclusion

In summary, CPVC FRP pipes present a revolutionary solution for industries requiring durable, reliable, and safe piping systems. Their outstanding attributes, including chemical resistance, temperature tolerance, and lower environmental impact make them an excellent choice for a variety of industrial applications. As industries evolve and prioritize efficiency, sustainability, and safety, the adoption of CPVC FRP pipes will likely continue to grow, establishing them as a cornerstone of modern piping solutions. Embracing such innovative materials is essential for the future of industrial applications, driving efficiency and reducing environmental impact in the process.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

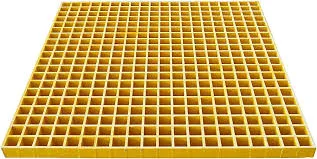

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025