-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

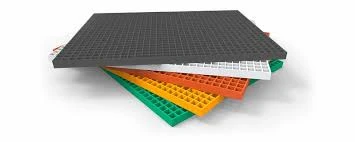

CPVC FRP Pipe Benefits for Industrial Use and Reliability in Harsh Environments

CPVC FRP Pipe A Reliable Choice for Industrial Applications

In the ever-evolving field of industrial materials, the demand for reliable, durable, and cost-effective piping solutions has never been greater. One such product that has gained considerable attention in recent years is the CPVC FRP (Chlorinated Polyvinyl Chloride Fiber Reinforced Plastic) pipe. This innovative piping system combines the advantageous properties of CPVC with the strength and durability of fiber-reinforced plastic, making it an excellent choice for various industrial applications.

The Composition and Benefits of CPVC FRP Pipes

CPVC is a thermoplastic material known for its superior resistance to heat and corrosion, unlike traditional PVC. When combined with a fiberglass reinforcement, the resulting CPVC FRP pipe exhibits enhanced structural integrity and flexibility. This unique combination allows it to withstand harsh chemical environments and extreme temperatures, making it particularly suitable for industries such as chemical processing, power generation, and water treatment.

One of the main benefits of CPVC FRP pipes is their resistance to corrosion. Many industrial environments expose piping systems to aggressive chemicals and abrasive materials. Traditional metal pipes often succumb to corrosion, leading to leaks, breakdowns, and costly downtime. In contrast, CPVC FRP pipes remain resilient in the face of chemical exposure, significantly extending their operational lifespan and reducing maintenance costs.

Additionally, the lightweight nature of CPVC FRP pipes simplifies installation and transportation. Unlike heavy metal piping, these pipes are easier to handle, reducing labor costs and allowing for faster installation times. Their adaptability means they can be used in various configurations, accommodating different industrial setups with ease.

Temperature and Pressure Resistance

cpvc frp pipe a reliable choice for industrial applications ...

Another crucial advantage of CPVC FRP pipes is their ability to withstand high temperatures and pressures. In many industrial processes, transporting hot liquids or gases is essential. CPVC can typically handle temperatures up to 200°F (93°C) while maintaining its structural integrity. This capability, combined with the strength of the fiberglass reinforcement, allows CPVC FRP pipes to be used in applications where metal pipes may fail or require costly insulation.

Moreover, these pipes can handle high pressure applications effectively, making them suitable for industries where pressure fluctuations are common. Their robust construction minimizes the risk of bursting or deforming under extreme conditions, instilling confidence among operators and decision-makers.

Environmental Considerations

In today's industrial landscape, environmental responsibility is paramount. CPVC FRP pipes contribute to sustainability efforts through their durability and reduced need for replacement. Their long lifespan translates to less waste in landfills and lower resource consumption over time. Additionally, CPVC is designed to have a low environmental impact during production and disposal, further aligning it with green initiatives.

Conclusion

In conclusion, CPVC FRP pipes represent a culmination of advanced materials engineering, boasting exceptional resistance to chemicals, pressure, and temperature while providing a lightweight, easy-to-install alternative to traditional piping materials. Their longevity and sustainability further enhance their status as a reliable choice for various industrial applications.

As industries strive for greater efficiency and reduced downtime, the adoption of CPVC FRP piping systems is set to rise. With their numerous benefits, these pipes not only meet the rigorous demands of modern industrial environments but also support businesses in their quest for innovation and sustainability. Investing in CPVC FRP pipes is not just a choice for today but a strategic decision for the future, ensuring reliability and durability in an unpredictable industrial landscape.