-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

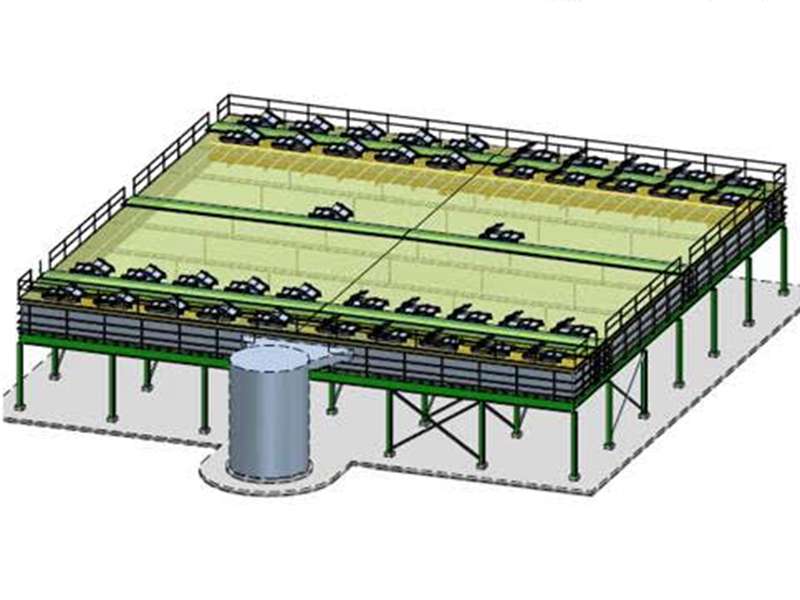

Durable CPVC FRP Tanks for Efficient Storage and Chemical Resistance Solutions

Understanding CPVC FRP Tanks A Comprehensive Overview

Corrosion-resistant materials have become pivotal in various industries, particularly in the storage and transportation of chemicals. Among these materials, CPVC (Chlorinated Polyvinyl Chloride) and FRP (Fiberglass Reinforced Plastic) tanks are gaining prominence due to their unique properties and benefits. This article delves into the characteristics, advantages, applications, and considerations regarding CPVC FRP tanks.

What is CPVC?

Chlorinated Polyvinyl Chloride, or CPVC, is a thermoplastic material that is derived from standard PVC through a chlorination process. This chemical modification enhances its properties, making CPVC more suitable for high-temperature applications. CPVC offers excellent resistance to corrosion, chemicals, and thermal degradation, making it an ideal choice for various industrial applications.

What is FRP?

Fiberglass Reinforced Plastic, or FRP, is a composite material made of a polymer matrix reinforced with fiberglass. This composite is known for its high strength-to-weight ratio, durability, and resistance to environmental factors. FRP combines the best of both worlds the lightweight nature of plastic with the robustness of fiberglass, making it incredibly effective for various applications, including tank construction.

The Synergy of CPVC and FRP

Combining the properties of CPVC and FRP results in a tank that offers significant advantages over traditional storage solutions. The hybrid material properties of CPVC FRP tanks provide enhanced resistance against harsh chemicals and temperature fluctuations. That makes them well-suited for industries such as chemical processing, wastewater treatment, and pharmaceuticals, where the integrity of the storage medium directly impacts operational safety and compliance with regulatory standards.

Key Advantages of CPVC FRP Tanks

1. Corrosion Resistance CPVC is known for its exceptional resistance to corrosive substances. When combined with the durability of FRP, CPVC FRP tanks protect stored materials from degradation and contamination.

2. Temperature Tolerance CPVC can withstand temperatures up to 200°F (93°C), making it suitable for hot chemical storage, while the FRP layer adds structural integrity, allowing for safe use under various environmental conditions.

cpvc frp tank

3. Lightweight CPVC FRP tanks are significantly lighter than metal tanks, making them easier to transport, install, and maintain. This feature not only saves on logistics costs but also reduces the structural requirements for supporting equipment.

4. Low Maintenance The robust nature of CPVC and FRP means that these tanks require minimal maintenance over their lifespan. This characteristic reduces operational downtime and maintenance costs, making them a cost-effective solution in the long run.

5. Customizability CPVC FRP tanks can be fabricated in various shapes and sizes, tailored to specific storage needs and applications. This flexibility allows for optimized space utilization in facilities.

Common Applications

CPVC FRP tanks find their application across multiple industries. Some of the most common include

- Chemical Storage Used extensively for storing acids, bases, and other hazardous chemicals safely. - Water Treatment Ideal for storing water and wastewater treatment chemicals due to their resistance to corrosive agents. - Food Processing Suitable for certain food applications where cleanliness and resistance to contamination are crucial. - Pharmaceuticals Used in the pharmaceutical industry for storing active ingredients and other sensitive materials that require a controlled environment.

Considerations

While CPVC FRP tanks come with numerous advantages, there are also considerations to keep in mind. It is crucial to assess the specific chemicals to be stored, as certain aggressive substances may still affect the integrity of CPVC. Additionally, installation practices must adhere to industry standards to ensure the longevity and reliability of the tanks.

Conclusion

In conclusion, CPVC FRP tanks represent an innovative solution for industries requiring durable, corrosion-resistant storage options. Their lightweight nature, combined with the exceptional chemical resistance of CPVC and the structural strength of FRP, makes these tanks a viable alternative to traditional materials. As industries increasingly seek efficient and sustainable storage solutions, CPVC FRP tanks are poised to play a vital role in meeting these demands, ensuring safety and compliance across various sectors.