-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 16, 2025 01:00

Back to list

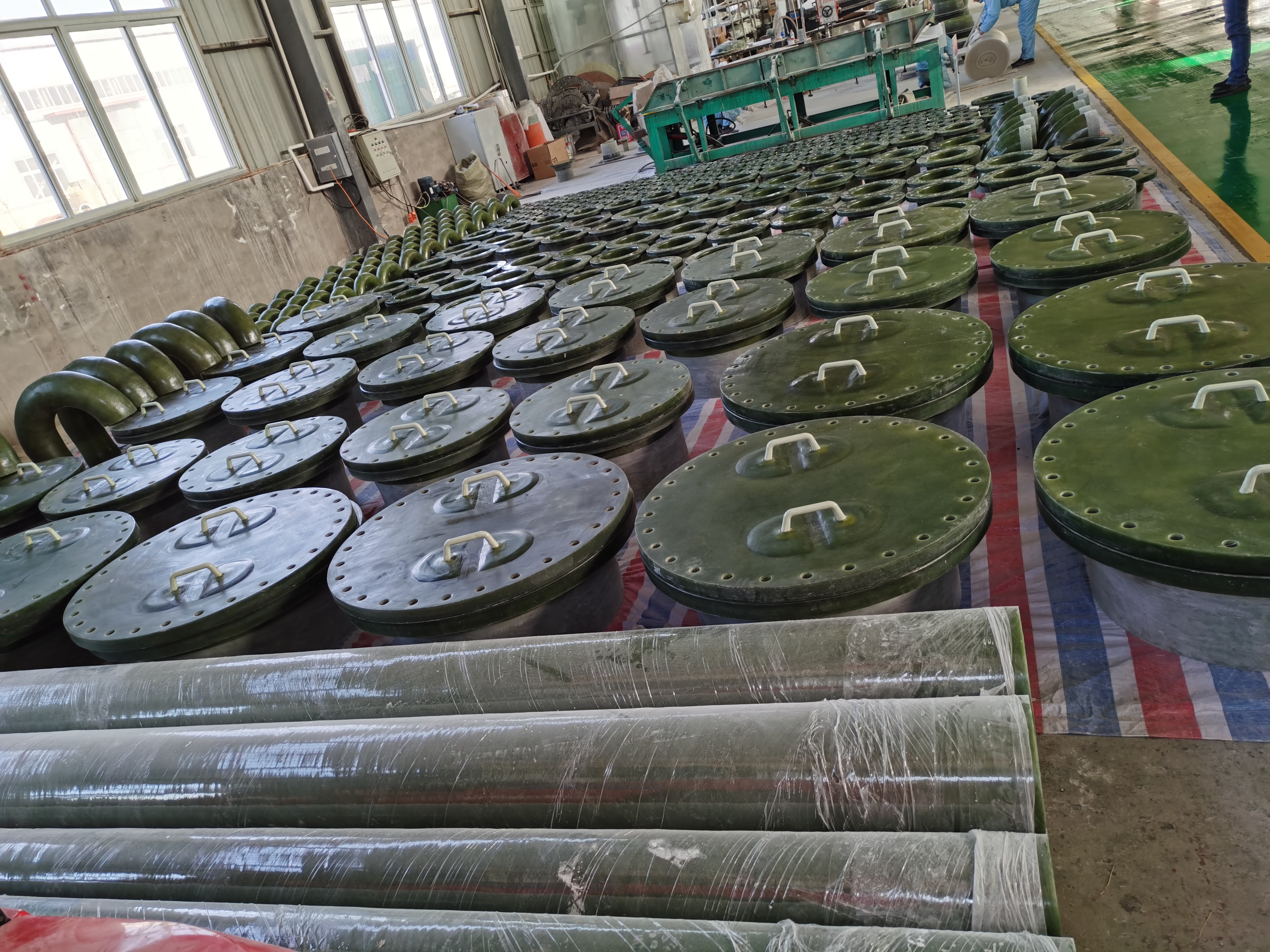

cpvc frp tank

Choosing the right storage solution for chemicals and liquids in industrial settings is pivotal to operational efficiency and safety. One of the most innovative and effective solutions available today is the CPVC FRP (Chlorinated Polyvinyl Chloride Fiber Reinforced Plastic) tank. This tank combines the robustness of fiberglass-reinforced plastic with the chemical resistance of CPVC, resulting in an exceptional product for a range of applications.

Trustworthiness is further augmented by rigorous testing and quality assurance processes put in place by reputable manufacturers. Each CPVC FRP tank undergoes stringent quality checks, from pressure tests to leak detection, ensuring the final product is reliable and meets industry standards. This level of oversight not only instills confidence among buyers but also sets a benchmark for quality in the industry. Moreover, the environmental aspect of using CPVC FRP tanks cannot be overlooked. As industries lean towards sustainable solutions, the recyclability of fiberglass components coupled with the low-energy production process of CPVC embodies a move towards environmentally responsible products. In addition, the longevity of these tanks reduces the frequency of replacements, subsequently diminishing material waste and resource consumption over time. From an authoritativeness perspective, top manufacturers and suppliers of CPVC FRP tanks are often trailblazers in engineering innovations and sustainable practices. They are allied with industry bodies and continually invest in research and development to refine their products. Their expert teams are well-versed in compliance with international standards and certifications, further reinforcing their products' credibility and reliability. Entities opting for CPVC FRP tanks can anticipate enhancements in operational efficiency and safety owing to the tanks' reliability and durability. The peace of mind that comes with knowing that critical storage solutions are resistant to leakage and environmental corrosion is invaluable. Thus, those needing robust storage options for industrial chemicals and liquids would find CPVC FRP tanks to be an optimal choice that exemplifies advanced material engineering, dedicated craftsmanship, and a commitment to quality and sustainability.

Trustworthiness is further augmented by rigorous testing and quality assurance processes put in place by reputable manufacturers. Each CPVC FRP tank undergoes stringent quality checks, from pressure tests to leak detection, ensuring the final product is reliable and meets industry standards. This level of oversight not only instills confidence among buyers but also sets a benchmark for quality in the industry. Moreover, the environmental aspect of using CPVC FRP tanks cannot be overlooked. As industries lean towards sustainable solutions, the recyclability of fiberglass components coupled with the low-energy production process of CPVC embodies a move towards environmentally responsible products. In addition, the longevity of these tanks reduces the frequency of replacements, subsequently diminishing material waste and resource consumption over time. From an authoritativeness perspective, top manufacturers and suppliers of CPVC FRP tanks are often trailblazers in engineering innovations and sustainable practices. They are allied with industry bodies and continually invest in research and development to refine their products. Their expert teams are well-versed in compliance with international standards and certifications, further reinforcing their products' credibility and reliability. Entities opting for CPVC FRP tanks can anticipate enhancements in operational efficiency and safety owing to the tanks' reliability and durability. The peace of mind that comes with knowing that critical storage solutions are resistant to leakage and environmental corrosion is invaluable. Thus, those needing robust storage options for industrial chemicals and liquids would find CPVC FRP tanks to be an optimal choice that exemplifies advanced material engineering, dedicated craftsmanship, and a commitment to quality and sustainability.

Next:

Related Products