-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

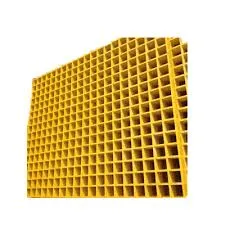

Customized Fiberglass Fittings for Unique Applications and Enhanced Performance Solutions

The Versatility and Advantages of Fiberglass Customized Fittings

In today's fast-paced industrial environment, the demand for customized solutions is greater than ever. One area where this is particularly relevant is in the field of fiberglass fittings. Fiberglass, a composite material made from fine glass fibers and resin, offers an array of benefits that make it an ideal choice for customized fittings across various applications. From construction to automotive and marine industries, fiberglass customized fittings are revolutionizing how we approach design and functionality.

Lightweight Yet Strong

One of the standout characteristics of fiberglass is its lightweight nature, which does not compromise its strength. This property allows for easier handling and installation compared to traditional materials like metal or concrete. Whether you need complex custom shapes or standard sizes, fiberglass fittings can be engineered to meet specific weight requirements while still providing robust structural integrity. This makes them particularly suitable for applications where minimizing weight is critical, such as aerospace and marine industries.

Corrosion Resistance

Fiberglass is inherently resistant to a range of corrosive environments, including chemicals, saltwater, and moisture. This quality significantly extends the lifespan of fittings in harsh conditions, making them an excellent choice for industries like oil and gas, wastewater management, and chemical processing. Customized fiberglass fittings can be designed to withstand specific environmental challenges, ensuring that they not only perform effectively but also reduce maintenance costs over time.

Design Flexibility

One of the primary advantages of fiberglass customized fittings is their design flexibility. The process of manufacturing fiberglass fittings allows for intricate shapes and sizes that are often difficult or impossible to achieve with traditional materials. Advanced techniques like resin transfer molding (RTM) and vacuum-assisted resin infusion enable manufacturers to create highly specialized components tailored to the client's exact specifications. Whether it's a unique duct, a bespoke joint, or a specialized connector, fiberglass can be molded and formed to meet a wide range of functional needs.

fiberglass customized fittings

Thermal and Electrical Insulation

Another notable feature of fiberglass is its excellent thermal and electrical insulation properties. This makes fiberglass fittings particularly beneficial in applications where heat resistance and non-conductivity are critical. For instance, in electronic enclosures or heat exchangers, customized fiberglass fittings can provide the required insulation, thereby enhancing safety and efficiency.

Environmental Considerations

With an increasing focus on sustainability across industries, fiberglass offers a relatively low environmental impact compared to other materials. The production of fiberglass fittings can be less energy-intensive, and many manufacturers are now adopting eco-friendly resins and production techniques. Additionally, fiberglass is recyclable, allowing for the potential to minimize waste and reduce the carbon footprint associated with producing new fittings.

Cost-Effective Solutions

While the initial investment in fiberglass fittings may be higher than some traditional materials, the long-term cost savings can be significant. The durability and corrosion resistance of fiberglass lead to lower maintenance and replacement costs. Additionally, reduced weight can lower shipping and handling fees, further contributing to overall project savings.

Conclusion

In summary, fiberglass customized fittings present a multitude of benefits that make them an attractive option for various industries. Their lightweight yet strong nature, combined with corrosion resistance, design flexibility, excellent insulation properties, and environmental benefits, positions them as a superior choice over conventional materials. As industries continue to evolve and demand more tailored solutions, fiberglass fittings will undoubtedly play a pivotal role in meeting those challenges head-on. Embracing fiberglass as a material for custom fittings not only enhances performance but also aligns with modern sustainability goals, driving innovation and efficiency into the future.