-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Overcoming Difficulties in Drilling Through Limestone Formations in the Field

Drilling Through Limestone Challenges and Solutions

Drilling through limestone presents a unique set of challenges that can significantly impact both the efficiency and the cost of construction and mining projects. Limestone, a sedimentary rock primarily composed of calcium carbonate, possesses physical properties that complicate the drilling process. Understanding these challenges is crucial for engineers, geologists, and drilling professionals to enhance their methodologies and optimize their workflow.

One of the primary challenges when drilling through limestone is its hardness. Although limestone is not as hard as granite, its brittleness can pose difficulties. When drill bits encounter this type of rock, they can experience rapid wear and tear, leading to the need for frequent replacements or re-sharpening. This not only increases project costs but also leads to extended downtime while new bits are procured and changed out. The cost of specialized drilling equipment designed for softer rock types can also be significantly higher, compounding the financial implications of drilling through limestone.

Drilling Through Limestone Challenges and Solutions

Another significant aspect to consider is the presence of water in the drilling environment. Many limestone formations are associated with aquifers, which can complicate the drilling process. The interaction of water with drilling mud can cause the mud to lack the necessary viscosity to carry cuttings up to the surface effectively. This may result in first-stage blockages and inefficient drilling. Furthermore, excessive water inflow can lead to issues such as mud loss, which necessitates additional time and resources to manage.

drilling through limestone is challenging.

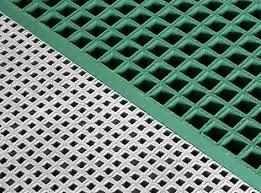

To address these challenges, various techniques and technologies can be employed. Advanced drilling technology, including rotary drilling techniques and more durable drill bits made of polycrystalline diamond compact (PDC) or tungsten carbide, can mitigate wear rates and improve drilling efficiency. These bits are designed to withstand the rigors of drilling through hard and abrasive materials, making them ideal for limestone formations.

Another vital strategy involves employing the correct drilling fluid. The selection of appropriate drilling mud can make a significant difference in the efficiency of the drilling process. Polymer-based muds or oil-based muds can enhance the carrying capacity of cuttings and reduce the likelihood of wellbore collapse, particularly in the presence of water. Properly designed additives can also help stabilize the formation and facilitate a more effective drilling operation.

Moreover, employing advanced geological surveying techniques prior to drilling can provide critical data about the subsurface conditions. Technologies such as 3D seismic imaging and borehole geophysical logging can help identify problematic zones within limestone layers and provide insights into fault lines or high-water zones. With this knowledge, drilling teams can better plan their approach, thereby minimizing risks and optimizing the drilling pattern.

In conclusion, while drilling through limestone poses significant challenges, understanding these issues allows for the development and implementation of effective strategies to overcome them. By investing in advanced technology, selecting the right drilling fluids, and conducting thorough geological assessments, drilling operations can enhance their efficiency and reduce costs. As the demand for limestone in construction, agriculture, and other industries continues to grow, addressing these challenges effectively will be essential for maintaining productivity and profitability in drilling projects. With the right approach and tools, even the toughest limestone formations can be penetrated, opening the door to their valuable resources.