-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

drilling through limestone is challenging.

The Challenges of Drilling Through Limestone

Limestone, a sedimentary rock predominantly composed of calcium carbonate, is a fundamental material in various industries, including construction, agriculture, and cement manufacturing. While drilling through limestone may seem straightforward at first, it presents a unique set of challenges that can complicate operations. Understanding these challenges is crucial for professionals in geology, engineering, and natural resource extraction.

One of the primary challenges of drilling through limestone is its hardness and abrasiveness. Although limestone is generally softer than igneous rocks such as granite, it can still present difficulties for drilling machinery. Over time, the drilling bits can wear down rapidly due to the abrasive particles within the limestone. This excessive wear necessitates frequent maintenance and replacement of drilling equipment, thereby increasing operational costs and time.

Additionally, limestone often contains various impurities and features such as fissures and voids. These irregularities can lead to unpredictable drilling conditions. Fissures can cause drill bits to deviate from the intended path, resulting in misalignment and loss of precision. Sudden voids within the rock can also lead to collapse or unexpected changes in drilling resistance, further complicating the task. To mitigate these issues, drill operators must engage in extensive geological surveys beforehand, which can extend the timeline of a project.

drilling through limestone is challenging.

Water infiltration is another significant challenge associated with drilling through limestone. The porous nature of limestone allows water to seep into the rock, creating potential hazards during the drilling process. Proper drainage and water management systems need to be in place to deal with any influx of water during drilling operations. Additionally, water can react with limestone to form karst features or cause erosion, which could destabilize the area being drilled. Therefore, extensive planning and engineering are required to manage groundwater effectively and ensure the integrity of the drilling site.

Moreover, another aspect that adds to the challenge of drilling through limestone is the potential for environmental impact. Limestone formations often serve as important groundwater reservoirs, and drilling can compromise these water sources if not managed correctly. Professionals must adhere to strict environmental regulations and conduct thorough environmental impact assessments before proceeding with any drilling operation. This aspect can not only increase the time and cost of drilling projects but also requires collaboration with environmental agencies and local communities.

Technology plays a vital role in addressing these challenges. Advanced drilling techniques, such as rotary drilling with specialized bits designed for limestone, can help improve efficiency and reduce wear on equipment. Additionally, real-time monitoring systems can assist operators in detecting changes in rock conditions, allowing for timely adjustments in drilling strategies.

In conclusion, while drilling through limestone is a common practice in various industries, it comes with its share of challenges. The hardness of the rock, irregular geological formations, water infiltration, and potential environmental impacts are all factors that must be carefully managed. By employing advanced technology and thorough planning, professionals can navigate these challenges, ensuring efficient and effective drilling operations while maintaining environmental integrity. As industries continue to rely on limestone for its vast applications, addressing these challenges will be critical in the pursuit of sustainable resource management.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

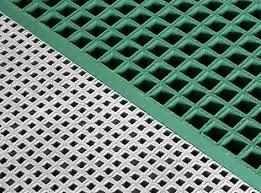

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025