-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Drill Rod Extension Techniques for Efficient Mine Exploration Operations

Drill Rod Extension for Mine Exploration Enhancing Efficiency and Depth

In the rapidly evolving field of mineral exploration, drill rod extension technology plays a pivotal role in enhancing the efficiency and accuracy of subsurface investigations. The significance of expansive and adaptable drilling techniques cannot be overstated, particularly in the pursuit of precious and base metal deposits. As industries increasingly demand more efficient resource extraction methods, the innovation surrounding drill rod extensions becomes paramount.

Drill rods serve as a fundamental component in drilling systems, bridging the drill bit to the surface equipment. Their primary function is to transmit rotational power and allow for the conveyance of drilling fluid. The extension of these drill rods is crucial, especially in mineral exploration, where geologists and mining engineers seek to reach greater depths to uncover valuable geological formations that lie beneath the surface.

Drill Rod Extension for Mine Exploration Enhancing Efficiency and Depth

Moreover, the use of extended drill rods streamlines various operational processes. With longer drill rods, the need for frequent drilling and reconfiguration is minimized, which can be both time-consuming and costly. The integrated design of drill rod extensions allows for seamless connection to the existing drilling apparatus, ensuring that operations can proceed with minimal disruption. Such efficiency translates into reduced operational costs and shorter timeframes for completing exploratory drills, thereby allowing laboratories and organizations to make faster decisions based on the data retrieved.

'drill rod extension for mine exploration.'

Another critical aspect of drill rod extension is its contribution to ensuring the integrity and safety of drilling operations. The extended rods are often engineered to withstand higher pressures and loads, reducing the chances of mechanical failure. In deeper drilling scenarios, where the geological conditions can be unpredictable, the robustness of extended drill rods becomes essential. Moreover, these extensions come equipped with advanced materials and technologies that enhance their durability, providing a longer lifespan and reducing the frequency of replacements.

In addition to conventional drilling techniques, drill rod extensions have paved the way for innovative directional drilling practices. Directional drilling allows operators to navigate around obstacles and reach targeted mineral deposits more effectively. With extended rods, directional drilling becomes not only feasible but also more precise. This capability is particularly advantageous in complex geological formations, enabling the exploration of deposits that would otherwise be inaccessible.

The integration of technology into drill rod extension has also revolutionized mining exploration. Modern drilling equipment often utilizes real-time monitoring systems that provide instant feedback on drilling performance. This data-driven approach allows for the optimization of drilling parameters, further enhancing the efficiency of the exploration process. Operators can analyze the data gained from extended drilling to make more informed decisions regarding future exploration strategies, advancing the overall effectiveness of mineral extraction operations.

In conclusion, drill rod extension technology represents a significant advancement in mine exploration. By enabling deeper and more efficient drilling, promising valuable mineral deposits can be uncovered more effectively than ever before. The combination of extended rods, enhanced operational efficiency, increased safety, and advanced technological integration positions this tool as indispensable in the quest for mineral resources. As the demand for raw materials continues to grow, innovations such as drill rod extensions will be essential in paving the way for sustainable and responsible mining practices. Ultimately, the evolution of drilling techniques will shape the future of mineral exploration, ensuring that industries are well-equipped to meet their resource needs.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

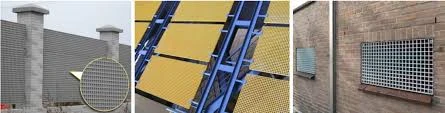

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025