-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

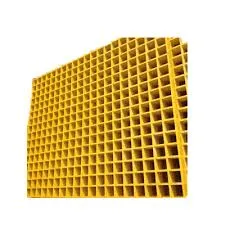

Durable Fiberglass Options for Enhanced Corrosion Resistance in Various Applications

The Advantages of Corrosion Resistant Fiberglass

In today's industrial landscape, the demand for durable and long-lasting materials is ever-increasing, particularly in environments that are harsh and corrosive. One of the most effective solutions for such applications is corrosion resistant fiberglass, which has emerged as a preferred alternative to traditional materials like metal and wood. This article explores the benefits and applications of corrosion resistant fiberglass, highlighting why it is indispensable in various industries.

What is Corrosion Resistant Fiberglass?

Corrosion resistant fiberglass, commonly known as fiberglass reinforced plastic (FRP), is a composite material made from a polymer matrix reinforced with glass fibers. This combination not only enhances the mechanical strength of the material but also provides significant resistance to chemical and environmental influences. Unlike metals, which are prone to rust and deterioration when exposed to moisture and corrosive substances, fiberglass remains stable and retains its properties over time.

Benefits of Corrosion Resistant Fiberglass

1. Superior Resistance to Corrosion One of the primary advantages of fiberglass is its resistance to corrosion. It can withstand exposure to harsh chemicals, acids, and salts, making it ideal for applications in chemical processing, wastewater treatment, and marine environments. This inherent resistiveness helps to reduce maintenance costs and extend the lifespan of equipment and structures.

2. Lightweight Yet Strong Fiberglass is considerably lighter than metals, which translates to easier handling and installation. Despite its light weight, it offers impressive strength and rigidity, making it suitable for various structural applications without compromising safety or stability.

corrosion resistant fiberglass

3. Versatile Applications The versatility of corrosion resistant fiberglass makes it suitable for numerous industries. It is extensively used in the construction of storage tanks, piping systems, and protective surfaces in chemical plants, oil refineries, and power generation facilities. Additionally, its aesthetic possibilities allow it to be employed in architectural designs where appearance and durability are equally important.

4. Cost-Effectiveness While the upfront cost of fiberglass can be higher compared to some materials, the long-term savings achieved through reduced maintenance, downtime, and replacement costs make it a wise economic choice. With its high durability and resistance to environmental factors, businesses can expect a favorable return on investment.

5. Low Thermal Conductivity Corrosion resistant fiberglass possesses low thermal conductivity, which makes it suitable for applications involving temperature fluctuations or extreme conditions. This property helps to insulate pipes, tanks, and other structures, enhancing energy efficiency and safety.

6. Environmental Friendly As industries shift towards more sustainable practices, fiberglass stands out as an environmentally friendly option. Its longevity reduces the need for frequent replacements, thereby minimizing waste. Moreover, many manufacturers are adopting eco-friendly production processes to create fiberglass, further contributing to sustainability.

Conclusion

In summary, corrosion resistant fiberglass is a groundbreaking material that offers numerous benefits across various industries. Its exceptional resistance to corrosion, lightweight nature, versatility, cost-effectiveness, low thermal conductivity, and environmental friendliness make it an ideal choice for tackling the challenges presented by aggressive environments. As technology continues to evolve, the applications for fiberglass are likely to expand, solidifying its position as a vital material in industrial and architectural projects. Embracing corrosion resistant fiberglass not only enhances the durability of structures and equipment but also promotes a sustainable future in material usage.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025