-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Optimized PDC Anchor Drill Bits for Enhanced Efficiency in High-Performance Drilling Applications

Efficient PDC Anchor Drill Bits for High-Performance Drilling

In the rapidly evolving field of drilling technology, the demand for high-performance tools has surged, particularly in the domains of oil and gas exploration, mining, and geothermal energy extraction. Among the array of drilling technologies, Polycrystalline Diamond Compact (PDC) drill bits have emerged as a front-runner, optimizing drilling efficiency and performance.

PDC drill bits consist of a matrix body embedded with synthetic diamond crystals, which are known for their exceptional hardness and wear resistance. This unique composition allows PDC bits to outperform traditional diamond or carbide bits in various challenging drilling applications. Their efficiency stems from the ability to sustain higher rates of penetration (ROP) while minimizing down-time due to wear and tear, ultimately leading to reduced operational costs and increased productivity.

One of the key benefits of PDC anchor drill bits is their ability to maintain stability and control even in complex geological formations. This characteristic is critical for anchor drilling applications, where precision is paramount. The robust design of these bits allows them to withstand the harsh conditions often encountered at significant depths, such as high-pressure environments and abrasive rock formations.

Moreover, the cutting structure of PDC bits is engineered to optimize chip removal and cooling during drilling operations. This design feature not only enhances the life expectancy of the bit but also improves drilling efficiency by reducing the likelihood of overheating. As a result, operators can maintain higher RPM, further contributing to increased penetration rates.

efficient pdc anchor drill bits for high-performance drilling ...

With the advancement of technology, the manufacturing process of PDC bits has also seen significant improvements. Modern machining techniques and advances in materials science have enabled the production of bits that are not only more durable but also specifically tailored to meet the unique requirements of different drilling environments. Customization options allow for modifications to the bit’s geometry, such as the size and arrangement of the diamond cutters, which can be optimized based on the rock types being drilled and the specific characteristics of the project.

In terms of application, PDC anchor drill bits are extensively utilized in both vertical and horizontal drilling operations. In oil and gas, for instance, these bits are crucial for the development of horizontal wellbores that require precision and efficiency in navigating diverse geological formations. In the geothermal sector, PDC bits excel in reaching deep reservoirs with high-temperature and high-pressure conditions, showcasing their versatility.

However, like any technology, PDC bits are not without their limitations. Their performance can be adversely impacted by certain geological challenges such as excessive abrasive rock conditions or significant changes in formation hardness. In such cases, proper bit selection and drilling parameters become essential for maintaining efficiency. Moreover, operators must be equipped with real-time data and monitoring systems to adaptively manage drilling variables, ensuring optimal performance.

In conclusion, efficient PDC anchor drill bits represent a significant advancement in the realm of high-performance drilling. Their ability to enhance penetration rates, reduce downtime, and maintain stability in complex environments makes them a preferred choice for modern drilling applications. As the industry continues to push towards greater efficiency and cost-effectiveness, the role of PDC technology is likely to expand further, paving the way for innovations that address the challenges of an ever-evolving landscape. By leveraging the benefits of PDC anchor drill bits, operators can achieve more sustainable and effective drilling operations, ultimately contributing to the broader goals of energy efficiency and resource management in the global market.

As the demand for energy continues to grow, the development and utilization of effective drilling technologies like PDC anchor drill bits will play an integral role in meeting these challenges head-on. The future of drilling is bright, and PDC technology stands at the forefront, continually driving advancements and efficiencies in the industry.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

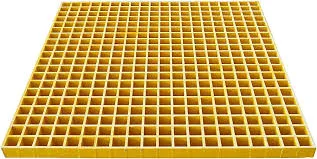

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025