-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Performance Drilling Solutions with Efficient PDC Anchor Drill Bits for Enhanced Productivity

Efficient PDC Anchor Drill Bits for High-Performance Drilling

In today’s fast-paced industrial landscape, the demand for high-performance drilling solutions has never been greater. One of the most significant advancements in this field has been the development of Polycrystalline Diamond Compact (PDC) drill bits, particularly designed for anchor drilling applications. These efficient PDC anchor drill bits are revolutionizing the drilling process across various industries, including oil and gas exploration, mining, and construction.

Understanding PDC Technology

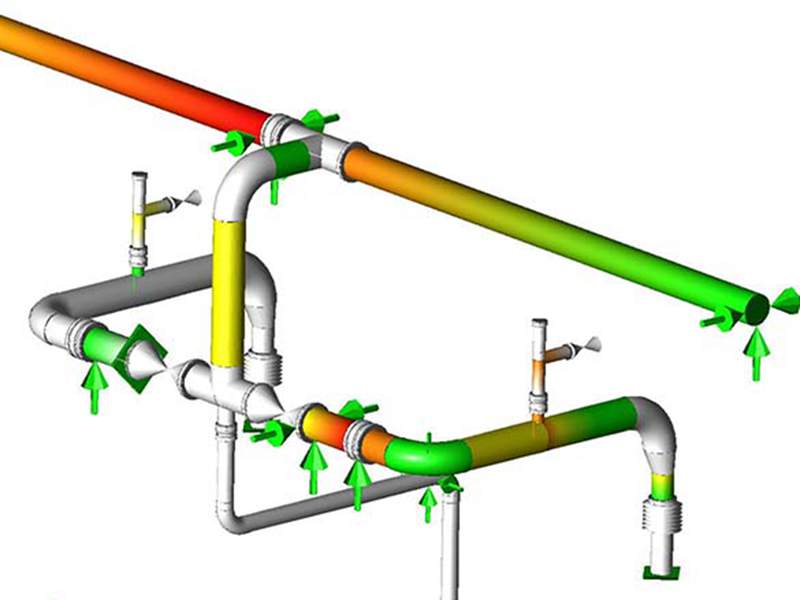

PDC drill bits consist of multiple diamond layers bonded with a cemented carbide matrix, resulting in incredibly durable and efficient drill bits. The unique composition of these bits allows them to withstand high temperatures and pressures while maintaining their cutting efficiency. Unlike traditional roller cone bits, which rely on the mechanical roller action to perform, PDC bits use a shearing action to cut through rock formations. This mechanism not only enhances speed but also enables cleaner holes with less vibration, leading to improved accuracy in drilling operations.

Advantages of PDC Anchor Drill Bits

1. Superior Abrasive Resistance One of the primary advantages of PDC anchor drill bits is their superior wear resistance. The diamond particles used in PDC construction significantly enhance the bit's performance in abrasive conditions, such as those found in rock formations filled with hard minerals. This durability translates to longer bit life and reduced frequency of replacements.

2. Efficient Cutting Performance PDC bits are designed for efficient cutting, which means they can drill faster and penetrate deeper than conventional bits. This efficiency is crucial in an era where time is synonymous with money. Faster drilling not only reduces operational costs but also minimizes the environmental footprint associated with drilling operations.

3. Reduced Vibration and Improved Stability The design of PDC anchor drill bits minimizes vibrations during the drilling process. This reduction in vibrations enhances the stability of the drill string and improves the overall quality of the drilling operation. The stability also reduces wear on the drilling equipment, leading to lower maintenance costs and extended operational life.

efficient pdc anchor drill bits for high-performance drilling ...

4. Customizable Designs Modern PDC drill bits can be tailored to meet specific drilling requirements. Engineers can adjust parameters such as bit size, shape, and the arrangement of cutting elements based on the geological conditions and the nature of the project. This flexibility ensures that drilling operations can be optimized for various environments, whether rocky terrains or softer sediment layers.

5. Environmental Considerations In recent years, there has been an increased focus on sustainable drilling practices. PDC anchor drill bits contribute to this movement by enabling efficient drilling processes that require less energy and generate reduced waste. Moreover, their capacity for fast and precise operations minimizes land disturbance, making them a more environmentally friendly option compared to traditional drilling methods.

Applications in Various Industries

The versatility of PDC anchor drill bits makes them suitable for various applications. In the oil and gas industry, they are extensively used in drilling horizontal and vertical wells, where penetration speed and bit longevity are crucial. In mining operations, these bits can be utilized to create effective anchor systems, ensuring stability and safety in excavated areas. The construction sector also benefits from PDC technology for foundation drilling, where precision and reliability are paramount.

Conclusion

As industries strive for efficiency and sustainability, the role of advanced drilling technologies like PDC anchor drill bits becomes increasingly vital. Their superior performance, durability, and adaptability make them a preferred choice for high-performance drilling applications. By investing in PDC technology, companies can enhance their operational efficiency, reduce costs, and minimize environmental impact.

In conclusion, efficient PDC anchor drill bits signify a breakthrough in the drilling industry, offering numerous advantages that contribute to the success of various operations. As technology continues to evolve, the future of drilling looks promising, with PDC bits leading the way towards more efficient and sustainable practices. The adoption of these innovative tools not only meets today’s demands but also paves the path for the challenges of tomorrow’s drilling environments.