-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Performance Drilling with Advanced PDC Anchor Drill Bits for Efficiency

Efficient PDC Anchor Drill Bits for High-Performance Drilling

In the realm of drilling technology, the demand for high-performance tools has never been higher. The efficient use of Polycrystalline Diamond Compact (PDC) anchor drill bits has emerged as a significant advancement, enabling operators to achieve exceptional results in various drilling applications. These drill bits are engineered to optimize performance, reduce costs, and enhance operational efficiency, making them an essential component in the toolkit of modern drilling operations.

PDC drill bits are renowned for their durability and effectiveness. The use of synthetic diamond materials offers superior wear resistance compared to conventional materials. This durability is particularly beneficial in challenging geological formations where traditional bits may struggle to maintain integrity. The ability to withstand high temperatures and abrasive conditions means that PDC bits can be operational for longer periods before needing replacement. This not only reduces downtime but also maximizes productivity.

One of the key factors contributing to the efficiency of PDC anchor drill bits is their design. PDC bits typically feature multiple cutting elements that allow for efficient penetration and reduced friction. The arrangement of these cutting edges is strategically planned to optimize the drilling trajectory, minimize energy consumption, and enhance rate of penetration (ROP). A well-designed PDC anchor drill bit can significantly improve drilling efficiency, resulting in substantial time and cost savings for the operator.

efficient pdc anchor drill bits for high-performance drilling ...

Moreover, PDC drill bits are highly versatile, making them suitable for a range of drilling applications including oil and gas exploration, mining, and geothermal drilling. Their ability to perform in diverse formations—from soft shale to hard granite—means that they can be utilized in various sectors. This adaptability not only simplifies inventory management for drilling companies but also allows for seamless switching between different geological conditions without the need for frequent bit changes.

An essential aspect of the operational efficiency offered by PDC anchor drill bits lies in their ability to be paired with advanced drilling technologies. The integration of real-time monitoring systems and automated drilling processes can further enhance the performance of PDC bits. By analyzing data on parameters such as weight on bit, rotary speed, and mud properties, operators can make informed adjustments during drilling operations. This data-driven approach not only improves efficiency but also prolongs the life of the PDC drill bit, making every drilling operation more cost-effective.

However, achieving the maximum efficiency from PDC anchor drill bits involves understanding the specific geological conditions and requirements of the drilling project. Different formations may require tailored strategies to ensure optimal performance. Operators need to thoroughly evaluate the rock type, hardness, and other relevant factors to select the appropriate PDC bit configuration. Engaging with manufacturers who can provide customized solutions based on these parameters is crucial in optimizing drilling efficiency.

In conclusion, the evolution of PDC anchor drill bits has had a transformative impact on high-performance drilling across various industries. Their inherent advantages—durability, versatility, and efficient design—combined with modern drilling technologies, enable operators to achieve remarkable results. As the industry continues to innovate, the importance of leveraging efficient PDC solutions will undoubtedly grow, underscoring the necessity for operators to stay informed and adapt to new advancements in drilling technology. By maximizing the potential of PDC anchor drill bits, companies can not only improve their operational efficiency but also contribute to a more sustainable and economically viable drilling future.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

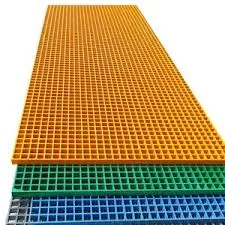

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025