-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Performance Anchored Drill Bits for Efficient PDC Drilling Applications

Efficient PDC Anchor Drill Bits for High-Performance Drilling

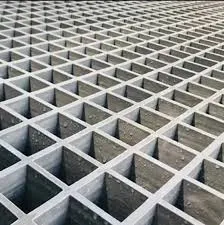

The drilling industry continuously seeks innovative solutions to enhance productivity and efficiency. Among the various advancements, Polycrystalline Diamond Compact (PDC) drill bits have emerged as a game-changer, particularly in anchor drilling operations. This article delves into the significance of efficient PDC anchor drill bits, their design features, and performance benefits, underscoring their role in achieving high-performance drilling.

Understanding PDC Drill Bits

PDC drill bits are cutting tools utilized in the drilling process, composed of layers of polycrystalline diamond bonded to a tungsten carbide substrate. The unique structure of these bits allows for superior hardness, wear resistance, and thermal stability. Unlike traditional drill bits, PDC bits provide a more aggressive cutting action, making them ideal for a variety of drilling applications, including oil and gas exploration, geothermal energy extraction, and mining operations.

In anchor drilling, the efficiency and effectiveness of the drill bit directly impact the overall success of the operation. Efficient PDC anchor drill bits are specifically designed to penetrate hard rock formations with minimal energy consumption and faster drilling times, leading to a more economical drilling process.

Design Features of Efficient PDC Anchor Drill Bits

The design of PDC anchor drill bits is crucial for their performance in challenging geological conditions. Key features of efficient PDC bits include

1. Optimized Cutter Geometry The arrangement and shape of the PDC cutters significantly influence the bit's ability to engage the rock. Modern PDC bits are designed with advanced cutter rows and the optimal spacing between them, facilitating deeper penetration and improved cutting efficiency.

2. Varied Cutter Concentration Different operational environments require varying cutter densities. Efficient PDC drill bits utilize a tailored concentration of cutters to provide necessary durability and efficiency, allowing for prolonged drilling times before bit wear becomes a concern.

3. Cooling and Cleaning Mechanisms Effective cooling and cleaning are essential in high-performance drilling. Many PDC bits incorporate advanced hydraulic designs that improve the flow of drilling mud across the bit face, ensuring optimal temperature management and removing cuttings efficiently from the borehole.

efficient pdc anchor drill bits for high-performance drilling

4. Enhanced Bit Stability The stability of a drill bit during operation is critical for maintaining the integrity of the borehole. Advanced design techniques, such as balanced weight distribution and robust construction materials, contribute to the operational stability of efficient PDC anchor drill bits.

Performance Benefits of PDC Anchor Drill Bits

The deployment of efficient PDC anchor drill bits offers numerous advantages

1. Increased Rate of Penetration (ROP) One of the primary benefits of PDC bits is their ability to achieve higher ROP compared to traditional bits. This acceleration in drilling speed translates to lower operational costs and increased productivity.

2. Extended Bit Life The durability of PDC materials allows these bits to withstand harsher drilling environments. As a result, operators experience reduced downtime, fewer bit replacements, and overall lower costs associated with tool wear.

3. Versatile Application Efficient PDC anchor drill bits can be employed in a variety of geological settings, from soft formations to hard rocks. This versatility makes them an ideal choice for various drilling operations, including anchor installations for slopes and retaining structures.

4. Improved Hole Quality Quality of the drilled hole is paramount in anchor drilling, as it influences the overall stability and effectiveness of the anchoring system. PDC bits yield straighter, more consistent holes, reducing the need for re-drilling or correctional measures.

Conclusion

Efficient PDC anchor drill bits represent a significant leap forward in drilling technology, providing a combination of enhanced performance, durability, and cost-effectiveness. With their optimized designs and superior cutting capabilities, these drill bits are indispensable tools in high-performance drilling operations across multiple industries. As the energy and construction sectors continue to evolve, the reliance on innovative tools like PDC anchor drill bits will undoubtedly increase, driving advancements in drilling efficiency and productivity. Investing in these technologies is essential for companies aiming to maintain a competitive edge in the ever-demanding landscape of drilling operations.