-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

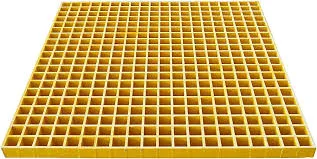

Mining Tools Featuring Durable Fiberglass Components for Enhanced Performance and Longevity

Equipment for Mining with Fiberglass Components

In recent years, the mining industry has witnessed significant advancements in technology, aiming to enhance efficiency, safety, and sustainability. Among these innovations, the use of fiberglass components has emerged as a compelling alternative to traditional materials. Fiberglass, a composite material made from glass fibers and resin, offers numerous advantages over metal and plastic counterparts, particularly in the demanding environment of mining operations.

Durability and Strength

One of the primary reasons for utilizing fiberglass in mining equipment is its remarkable durability. Fiberglass structures resist corrosion, which is particularly beneficial in mining environments where exposure to chemicals and harsh weather conditions is common. Unlike metal components that can rust and degrade over time, fiberglass remains resilient and maintains its structural integrity under extreme conditions. This durability translates into longer equipment lifespans and reduced maintenance costs, providing significant economic advantages for mining operations.

Moreover, fiberglass is lightweight yet strong, making it an ideal material for equipment that needs to be transported to remote mining sites. Lighter equipment not only reduces transportation costs but also minimizes fuel consumption during operations. As mining activities often take place in inaccessible locations, the portability of fiberglass components can streamline logistics and enhance operational efficiency.

Safety Considerations

The safety of workers in the mining industry is of utmost importance, and fiberglass components contribute to this goal through their non-conductive properties. In an environment where electrical hazards are prevalent, having equipment made from non-conductive materials reduces the risk of electrocution. Additionally, fiberglass is less prone to breaking compared to brittle materials, which mitigates the risk of injury from shattering or splintering.

Furthermore, the use of fiberglass in safety gear, such as helmets and protective barriers, offers improved protection for miners. The impact resistance and lightweight nature of fiberglass make it an excellent choice for personal protective equipment (PPE), allowing workers to remain agile while ensuring their safety in rugged terrains.

equipment for mining with fiberglass components

Cost-Effectiveness

While the initial investment in fiberglass equipment may be higher than traditional materials, the long-term savings are undeniable. The reduced maintenance requirements, extended lifespan, and enhanced efficiency all contribute to lower overall operational costs. Mining companies are increasingly recognizing the importance of cost-effectiveness in their equipment choices, and fiberglass components provide a favorable balance between performance and affordability.

Additionally, manufacturers are continuously innovating in the realm of fiberglass production, driving down costs through improved production techniques and scalability. As the technology matures, the price of fiberglass components is expected to become more competitive, making them an attractive option for even more mining applications.

Environmental Impact

The mining industry faces increasing pressure to adopt sustainable practices, and fiberglass components align well with these goals. Fiberglass is often made from recycled materials, and the processes involved in its production can be less harmful to the environment than those for metals. Moreover, the longevity and durability of fiberglass reduce the need for frequent replacements, which consequently minimizes waste.

As the industry shifts towards greener practices, adopting fiberglass components can enhance a mining company’s sustainability profile. Companies that prioritize eco-friendly technologies are likely to appeal to investors and customers who are increasingly concerned about environmental responsibility.

Conclusion

The integration of fiberglass components into mining equipment presents numerous advantages ranging from durability and safety to cost-effectiveness and environmental sustainability. As the mining industry continues to evolve, leveraging the benefits of fiberglass can lead to enhanced operational efficiencies and improved worker safety. As a forward-thinking solution, fiberglass is set to become a standard in modern mining equipment, guiding the industry towards a more sustainable and efficient future. Embracing this technological advancement not only benefits mining companies economically but also contributes positively to the industry's impact on the environment and society.