-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring Advanced Technologies in Tunnel Rock Drill Bits for Enhanced Mining and Construction Efficiency

Tunnel Rock Drill Bits Essential Tools for Underground Excavation

In the world of construction and mining, the efficient and effective excavation of tunnels is crucial for the development of infrastructure and resource extraction. One of the most important tools in this process is the tunnel rock drill bit. These specialized drill bits are designed to bore through various types of rock and soil, making them indispensable for engineers and contractors engaged in underground projects.

Understanding Tunnel Rock Drill Bits

Tunnel rock drill bits come in a variety of shapes, sizes, and materials, each tailored to specific geological conditions and project requirements. The primary function of these drill bits is to penetrate hard rock formations, which can be a daunting task due to the immense pressure and friction involved. Most drill bits used in tunnel construction feature a conical shape equipped with hardened steel or tungsten carbide tips, designed to cut through rock efficiently.

One of the most common types of tunnel rock drill bits is the roller cone bit, which utilizes rotating cones to crush and grind the rock as it is drilled. This bit is particularly effective in diverse geological settings, where the rock's hardness may vary significantly. Additionally, there are fixed-cutter bits that incorporate various cutting elements and can be used in softer rock formations.

The Importance of Material Selection

The materials used in the construction of tunnel rock drill bits are vital for their performance and durability. High-grade steel alloys and tungsten carbide are often employed to ensure the bits can withstand the extreme conditions encountered during drilling. The choice of material influences the bit's resistance to wear, heat generation, and overall longevity, making it a critical factor in cost-effectiveness and project timelines.

Advances in Technology

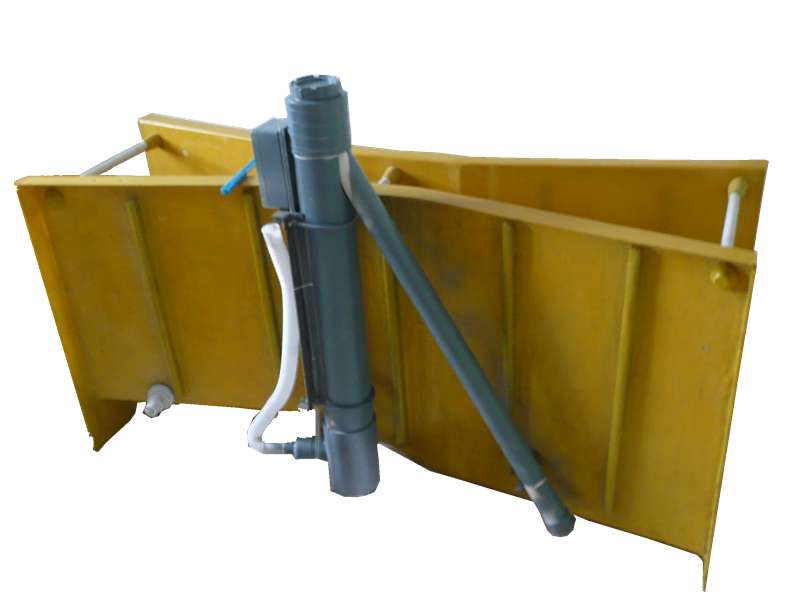

tunnel rock drill bits

In recent years, advancements in technology have greatly improved the design and efficiency of tunnel rock drill bits. Computer-aided design (CAD) and simulation software allow manufacturers to optimize bit geometry for specific applications, ensuring better performance in various rock formations. Additionally, innovations such as enhanced cooling and lubrication systems have been developed to reduce friction and heat, leading to improved drilling efficiency and longer service life.

Environmental Considerations

As the demand for infrastructure grows, so too does the focus on sustainable practices in construction and mining. Tunnel rock drill bits are now being designed with environmental considerations in mind. For instance, there is a growing trend to develop bits that minimize dust and vibration, reducing the ecological impact of tunneling operations. Some manufacturers are also exploring alternative materials and processes that lessen the environmental footprint associated with the production and use of drill bits.

Challenges Ahead

Despite advancements, the field of tunnel rock drilling is not without its challenges. The variability of geological conditions can greatly affect the performance of drill bits. Unpredictable rock formations may lead to increased wear and tear or even failure of the drill bit, resulting in delays and additional costs. Moreover, the increasing depth and complexity of modern tunneling projects pose new challenges that require continuous innovation in drill bit technology.

Conclusion

Tunnel rock drill bits are crucial components in the successful completion of underground projects. As technology continues to evolve, we can expect to see even more sophisticated designs that enhance efficiency, durability, and environmental sustainability. For engineers and contractors alike, understanding the capabilities and limitations of different types of drill bits is essential for overcoming the challenges associated with tunnel excavation. Ultimately, the ongoing development of tunnel rock drill bits will play a significant role in shaping the future of construction and mining, paving the way for more effective underground exploration and resource utilization.