-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Benefits and Applications of Integral Drill Rods in Modern Drilling Techniques

The Integral Drill Rod A Comprehensive Overview

The integral drill rod has emerged as a pivotal component in the drilling industry, particularly in geotechnical and mining applications. This innovative design combines the drill bit and rod into a single piece, offering numerous advantages over traditional segmented systems. Understanding its features, applications, and benefits is essential for professionals in the drilling sector to maximize efficiency and effectiveness in their operations.

Features of Integral Drill Rods

Integral drill rods are crafted from high-quality materials, typically high-strength steel or alloy metals, ensuring durability and resistance to wear and tear. The key characteristic of these rods is their seamless, continuous design, which enhances the integrity of the tool while minimizing the risk of failure. This construction leads to improved energy transfer from the drill rig to the drill bit, facilitating more effective cutting action and penetration.

Moreover, integral drill rods often come with specialized coatings or treatments that enhance their performance in various conditions. For instance, heat treatment can elevate the hardness of the rod, increasing resistance to abrasion and impact. Some manufacturers also employ advanced friction welding techniques to ensure the highest quality and strength, offering long-lasting performance in challenging environments.

Applications in Various Industries

Integral drill rods find extensive applications across multiple sectors, including mining, construction, and environmental drilling. In the mining industry, they are widely used for exploration and production drilling. The enhanced structural integrity helps in reaching greater depths and handling challenging rock formations, making them indispensable for mineral extraction processes.

integral drill rod

In construction, integral drill rods play a crucial role in site preparation and foundation drilling. Their efficiency allows for quicker penetration into the ground, reducing project timelines and costs. Environmental drilling also benefits from these rods, particularly in groundwater sampling and monitoring, where precision and reliability are paramount.

Benefits of Using Integral Drill Rods

The integration of drill bit and rod results in several significant advantages. First and foremost is increased durability. Without joints or connections, integral drill rods eliminate weak points that could lead to failures, translating to less downtime and fewer interruptions in operations. This reliability is crucial for projects with tight deadlines and high financial stakes.

Additionally, the streamlined design of integral drill rods improves the overall efficiency of drilling operations. They require less energy to operate than traditional systems, which can lead to cost savings in terms of fuel and machine wear. The reduced vibration and improved balance of these rods also contribute to extended tool life and lower maintenance requirements.

Another noteworthy benefit is the enhanced safety they offer. Fewer components mean there are fewer opportunities for equipment malfunction. This can significantly reduce the risk of accidents on job sites, fostering a safer working environment for crews.

Conclusion

Integral drill rods represent a significant advancement in drilling technology, merging efficiency, reliability, and safety into a single tool. Their seamless design, durability, and performance advantages make them a preferred choice for various industries. As drilling technologies continue to evolve, the integral drill rod is likely to remain at the forefront, driving innovations that enhance productivity and reduce costs. For professionals in the drilling sector, investing in integral drill rods can yield substantial long-term benefits, positioning them for success in an increasingly competitive market.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

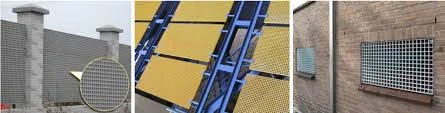

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025