-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Benefits and Applications of Tapered Drill Rods in Modern Drilling Techniques

The Significance of Tapered Drill Rods in Modern Drilling Operations

Tapered drill rods are a critical component in various drilling operations, particularly in industries such as mining, geotechnical drilling, and oil exploration. These specialized drill rods feature a tapered design, which means that their diameters gradually decrease from one end to the other. This design serves multiple purposes that enhance drilling efficiency and effectiveness. In this article, we will explore the advantages, applications, and significance of tapered drill rods in modern drilling practices.

Advantages of Tapered Drill Rods

One of the most notable advantages of tapered drill rods is their ability to reduce friction during drilling operations. The conical design minimizes the contact area between the rod and the borehole wall, allowing for smoother penetration into the ground. This reduction in friction leads to lower energy consumption and enhanced drilling speed, making tapered rods an economical choice for drilling contractors.

Additionally, the tapered design allows for better alignment of the drill bit with the borehole. When a drill rod enters a narrow opening, the taper helps guide the larger diameter at the other end into place, ensuring a more accurate drilling trajectory. This feature is particularly essential when working in tight or uneven spaces, where precision is crucial.

Tapered drill rods also improve the overall durability of drilling equipment. The gradual taper minimizes stress concentrations that often lead to fatigue and breakage, resulting in a longer lifespan for the rods. This enhanced durability translates to less downtime for equipment repairs and replacements, ultimately improving the return on investment for drilling operations.

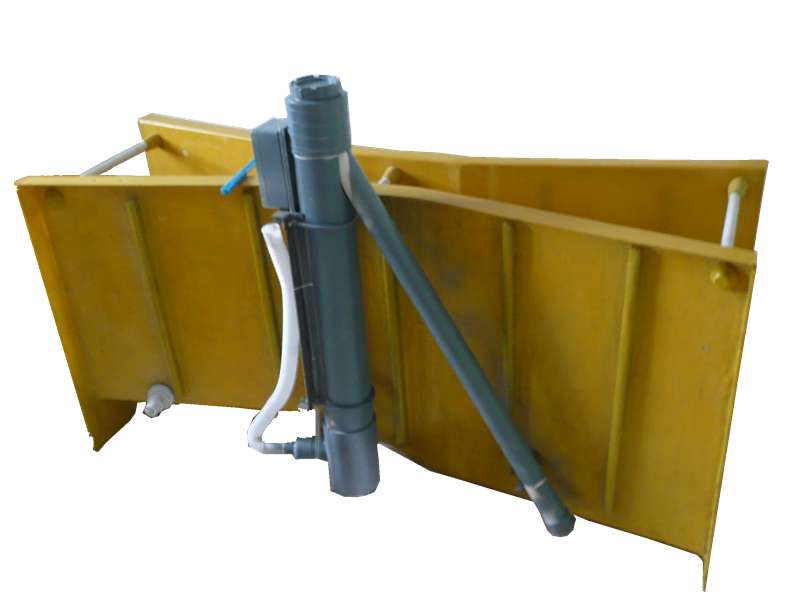

tapered drill rod

Applications in Various Industries

Tapered drill rods are utilized across a variety of industries, each benefiting from their unique advantages. In the mining industry, for example, these rods are essential for exploration and production drilling. They allow miners to obtain core samples from various depths, providing valuable geological data for evaluation and decision-making.

In geotechnical engineering, tapered drill rods are used to assess soil and rock conditions before construction projects. Engineers perform borehole drilling to collect information about the subsurface material, ensuring that foundations are built on stable ground. The tapered design facilitates drilling in challenging geological scenarios, enabling engineers to gather precise data efficiently.

Oil and gas exploration also employs tapered drill rods as they navigate the complexities of underground drilling. The ability to maintain accurate depth control and reduce friction can significantly impact the success of drilling operations in locating and extracting hydrocarbons.

Conclusion

In conclusion, tapered drill rods play a vital role in enhancing the efficiency and effectiveness of drilling operations in various industries. Their unique design not only reduces friction and improves alignment but also extends the lifespan of drilling equipment. Whether in mining, geotechnical, or oil and gas industries, the benefits of tapered drill rods are undeniable. As technology advances and the demand for efficient drilling solutions continues to grow, the significance of these specialized drill rods will undoubtedly remain critical to the success of drilling projects worldwide. Investing in high-quality tapered drill rods is an investment in operational excellence, paving the way for more sustainable and efficient resource extraction.