-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

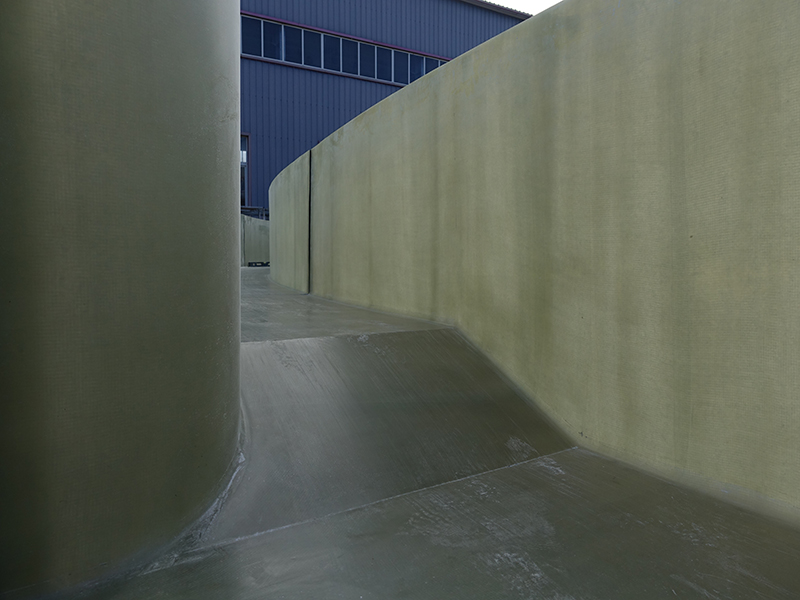

Innovative Approaches to Optimize FRP Laundering Processes for Increased Efficiency

Exploring Efficient Methods for Streamlining FRP Laundering

Fiber-Reinforced Plastic (FRP) materials have become increasingly popular in various industries due to their lightweight, durability, and corrosion resistance. However, the laundering and recycling of these materials represent significant challenges. The need to streamline FRP laundering methods is imperative for enhancing sustainability, reducing environmental impact, and optimizing resource use.

Exploring Efficient Methods for Streamlining FRP Laundering

Chemical methods also present a viable option for efficiently laundering FRP. Solvent-based processes can selectively dissolve the resin, leaving behind the reinforcing fibers. This method allows for a cleaner separation and retention of the fibers' quality. However, the environmental impact of solvents must be considered. The development of eco-friendly solvents or alternative chemical processes could mitigate this concern while promoting sustainability.

exploring efficient methods for streamlining frp laundering

Moreover, innovations in recycling technologies are crucial for enhancing FRP laundering practices. For instance, closed-loop recycling systems can efficiently process FRP waste by reusing the recovered materials in the production of new products, thus minimizing waste. Additionally, incorporating automation and smart technologies into the laundering process can optimize operational efficiency. Automated systems can monitor and adjust parameters in real time, ensuring optimal performance and consistency in the laundering process.

Collaboration among industries, researchers, and policymakers is essential to drive forward these innovations. Establishing standard practices for FRP laundering and recycling can create a more uniform approach, making it easier for companies to adopt effective methods. Furthermore, educational initiatives aimed at raising awareness of the significance of FRP recycling can foster a culture of sustainability within the industry.

In conclusion, streamlining the laundering of FRP materials is vital for reducing environmental impact and promoting a circular economy. By exploring advanced mechanical and chemical methods, leveraging recycling technologies, and fostering collaboration, industries can enhance the efficiency of FRP laundering processes. This effort not only serves the interests of businesses but also contributes to a more sustainable future for materials management, underlining the importance of responsible manufacturing in today’s world.