-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Drilling Bit Technologies in Gold Mining for Improved Efficiency and Performance

Exploring Innovations in Gold Mining Drilling Bits for Enhanced Efficiency

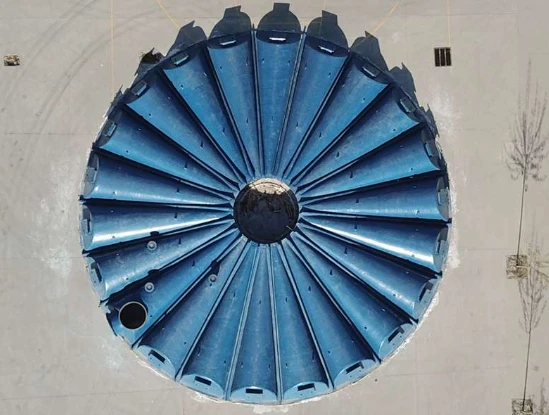

In recent years, the gold mining industry has experienced a significant transformation fueled by advancements in technology and innovation. One of the critical areas where these advancements have made a substantial impact is in the development of drilling bits. The efficiency and effectiveness of drilling operations have a direct correlation with the performance of drilling bits, making their innovation a focal point for researchers and industry professionals alike.

Traditionally, drilling bits have been made from materials such as high-carbon steel and tungsten carbide. While these materials provided adequate performance, they often fell short in terms of durability and efficiency, leading to higher operational costs and increased downtime. To address these challenges, the industry has turned towards more advanced materials and design techniques. The use of polycrystalline diamond compact (PDC) bits, for instance, represents a significant step forward. PDC bits are crafted from synthetic diamonds bonded to a tungsten carbide substrate, allowing them to maintain sharp cutting edges for longer periods and enhancing their ability to penetrate rock formations efficiently.

Another promising innovation is the incorporation of smart technology into drilling bits. Integrated sensors can provide real-time data on parameters such as temperature, pressure, and vibration. This data is invaluable for monitoring the performance of drilling operations and can help optimize drilling parameters on-the-fly. By analyzing this data, operators can adjust their drilling techniques to improve penetration rates and reduce wear on the bits, ultimately leading to reduced operational costs and increased safety.

exploring innovations in gold mining drilling bits for enhanced ...

Furthermore, advancements in bit design are also playing a crucial role in enhancing drilling efficiency. Modern drilling bits are now being designed using computer-aided design (CAD) and finite element analysis (FEA) techniques, allowing for more precise and effective shapes tailored to specific geological conditions. The optimization of bit geometry, including the arrangement of cutting elements and the configuration of fluid channels, can significantly influence drilling performance. These customized designs help to minimize the energy required for drilling and improve the removal of cuttings, leading to faster and more efficient operations.

Environmental considerations are also driving innovation in drilling technologies. The mining industry faces increasing scrutiny regarding its environmental impact, and more sustainable practices are becoming imperative. Innovations such as eco-friendly drilling fluids and energy-efficient drilling techniques are being developed to minimize the ecological footprint of mining operations. By utilizing biodegradable drilling fluids and optimizing drilling practices to reduce energy consumption, companies can improve their sustainability while also cutting costs.

Moreover, the integration of artificial intelligence (AI) and machine learning into the drilling process is revolutionizing how companies approach gold mining. AI algorithms can analyze vast datasets to predict the optimal moments for bit replacement and intervention, reducing human error and enhancing operational efficiency. Predictive maintenance powered by AI can also anticipate potential failures before they occur, allowing operators to perform maintenance proactively and reduce unexpected downtimes.

In conclusion, the exploration of innovations in gold mining drilling bits is not merely an operational enhancement; it is a transformative change that promises to shape the future of the gold mining industry. With advancements in materials, smart technologies, design optimization, and sustainability practices, the drilling process can become significantly more efficient, reliable, and environmentally friendly. As the industry continues to evolve, it is clear that embracing these innovations is critical not only for enhancing productivity but also for ensuring the long-term viability of gold mining operations worldwide.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025