-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

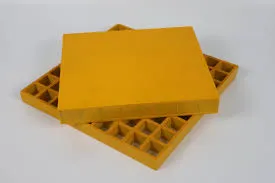

extension rod for mining

Extension Rods in Mining Enhancing Efficiency and Safety

In the mining industry, the quest for efficiency and safety is never-ending. As miners descend into the earth, they face various challenges, including difficult terrain, hazardous conditions, and the need for precise operations. One essential tool that has emerged to address some of these challenges is the extension rod. These rods play a crucial role in the mining process, particularly in drilling and exploration activities.

What are Extension Rods?

Extension rods are specialized equipment used in drilling operations. They serve as an intermediary between the drilling machine and the drill bit, allowing operators to extend the reach of their equipment. Typically made from high-strength materials, extension rods are designed to withstand the rigors of demanding mining environments. Their length can vary, enabling miners to adapt their configuration based on the depth and type of mining they are conducting.

Applications in Mining

Extension rods are primarily used in drilling applications, including exploration drilling and production drilling. In exploration, geologists use these rods to reach deeper into the ground to extract core samples. These samples are crucial for determining the viability and richness of mineral deposits. The flexibility offered by extension rods allows for more thorough investigation of potential mining sites, thus reducing the risk of investing in unproductive areas.

In production drilling, extension rods are used to enhance the efficiency of resource extraction processes. By allowing drilling to proceed deeper without the need for multiple disconnects and reconnects of drilling equipment, these rods help maintain continuous operation. This efficiency can lead to substantial cost savings and improved productivity.

Advantages of Using Extension Rods

extension rod for mining

One significant advantage of extension rods is their ability to enhance safety. Mining is inherently dangerous, with risks ranging from cave-ins to equipment failures. Extension rods help minimize the time miners spend underground and reduce their exposure to hazardous conditions. By allowing operators to drill more efficiently, these rods contribute to safer work environments.

Moreover, extension rods facilitate precision drilling. The accurate positioning of drill bits is vital in mining operations, particularly when working near existing underground infrastructure or when targeting specific mineral veins. The use of extension rods ensures that drill bits can be placed accurately, helping to avoid costly errors and increasing overall extraction rates.

Technological Advancements

Recent advancements in materials science and engineering have led to the development of more robust and lightweight extension rods. Innovations such as composite materials and improved manufacturing techniques have enhanced the strength-to-weight ratio of these rods. This progress not only makes them easier to handle but also allows for longer extensions without compromising structural integrity.

Additionally, the integration of technology in mining operations has led to the adoption of smart monitoring systems that can work in tandem with extension rods. Sensors can be embedded in these rods to provide real-time data about the drilling process, helping operators make informed decisions and quickly address any issues that arise.

Conclusion

Extension rods are a vital component in the mining industry, contributing to the safety, efficiency, and precision of drilling operations. As mining becomes more sophisticated, the importance of such tools will only continue to grow. By leveraging advancements in materials and technology, the mining sector can further enhance the capabilities of extension rods, ultimately leading to better resource extraction practices and safer working conditions for miners. As the industry evolves, the role of extension rods will remain essential in navigating the challenges and opportunities of modern mining.