-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

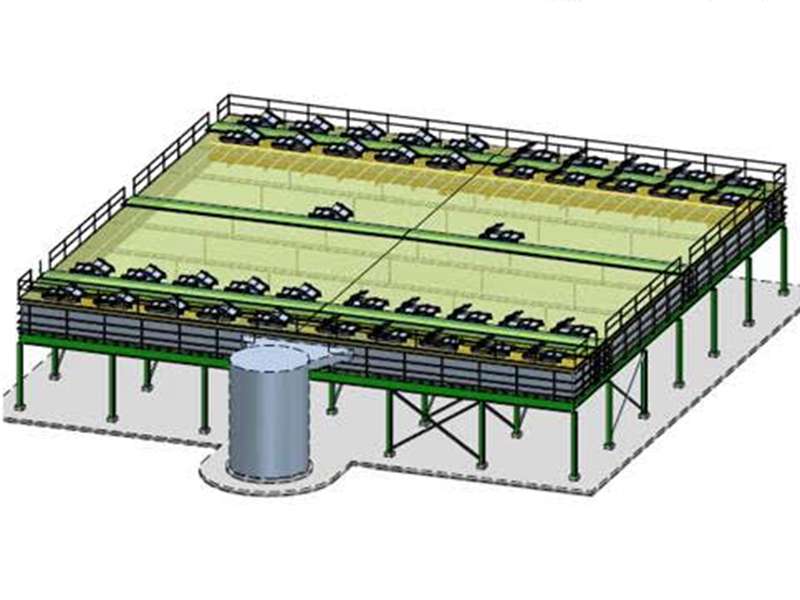

fiberglass agitating tank

The Importance of Fiberglass Agitating Tanks in Industrial Applications

Fiberglass agitating tanks are essential components in various industrial processes, particularly in the chemical, food and beverage, and pharmaceutical sectors. These tanks are designed to mix, blend, and agitate liquids, ensuring uniform consistency and optimal quality of the end product. The use of fiberglass in their construction offers several advantages, making them a preferred choice for many manufacturers.

One of the primary benefits of fiberglass agitating tanks is their durability. Fiberglass is resistant to corrosion, which is crucial when dealing with aggressive chemicals. This resilience significantly extends the lifespan of the tanks compared to those made from metal or other materials susceptible to rust and degradation. With lower maintenance requirements and reduced replacement costs, businesses that utilize fiberglass tanks can improve their operational efficiency and reduce downtime.

Moreover, fiberglass tanks are lightweight yet robust, making them easier to install and relocate if necessary. This characteristic is particularly beneficial for companies that may need to adapt their production facilities or shift to different locations. The ease of installation not only saves time but also reduces labor costs associated with tank transport and setup.

fiberglass agitating tank

In addition to their physical properties, fiberglass agitating tanks can be engineered for specific tasks. Manufacturers can customize tank designs to meet varying needs, including different shapes, sizes, and agitation methods. For instance, some processes require gentle mixing, while others may demand intense agitation. With advanced molding techniques, fiberglass can be shaped to create specialized features, such as baffles or internal mixers, which enhance the mixing capabilities.

Furthermore, fiberglass tanks are designed with safety in mind. They can be equipped with features that minimize the risk of spills and accidents, which is critical in environments handling hazardous materials. The smooth surfaces of fiberglass also facilitate cleaning and sanitation, crucial in sectors like food processing where hygiene is paramount.

In conclusion, fiberglass agitating tanks play a vital role in modern industrial operations. Their resistance to corrosion, lightweight nature, customization options, and safety features make them an ideal choice for a variety of applications. As industries continue to evolve and seek more efficient, cost-effective solutions, the popularity of fiberglass agitating tanks is likely to grow. Manufacturers that invest in these tanks can expect enhanced productivity and quality in their processes, ultimately leading to greater customer satisfaction and business success. Whether used in large-scale production or small batch processes, fiberglass agitating tanks are indispensable tools that support innovation and excellence in manufacturing.