-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Quality Fiberglass Chemical Products for Industrial Applications

Fiberglass Chemical Products Innovations and Applications

Fiberglass, a composite material made from fine fibers of glass, is renowned for its strength, lightweight properties, and versatility. The chemical products associated with fiberglass play a crucial role in enhancing its performance and expanding its applications across various industries. From construction to automotive and aerospace, fiberglass chemical products have carved a niche due to their unique properties and benefits.

At the core of fiberglass production are resin systems, primarily polyester and epoxy resins, which are essential for binding the glass fibers together. Polyester resins are widely used due to their cost-effectiveness and ease of application. They offer good mechanical properties and resistance to UV light, making them suitable for outdoor applications, such as in boat building and roofing materials. On the other hand, epoxy resins provide superior strength, chemical resistance, and durability, making them a preferred choice in high-performance applications like aerospace and high-end automotive components.

The advancement of fiberglass chemical products is closely tied to innovation in resin formulation. Newer formulations are emerging that enhance the properties of traditional resins. For instance, the introduction of hybrid resins combines the best characteristics of polyester and epoxy, achieving improved mechanical properties and reduced cure times. Moreover, advancements in curing agents and additives are also transforming the sector, allowing for better control over the curing process, which ultimately leads to enhanced performance of the fiberglass.

fiberglass chemical product

One of the most significant trends in the fiberglass industry is the move towards sustainability. Many manufacturers are now focusing on eco-friendly resin systems that contain reduced levels of volatile organic compounds (VOCs). Bio-based resins made from renewable resources are also gaining traction. These sustainable options not only help minimize environmental impact but also cater to a growing market demand for green building materials.

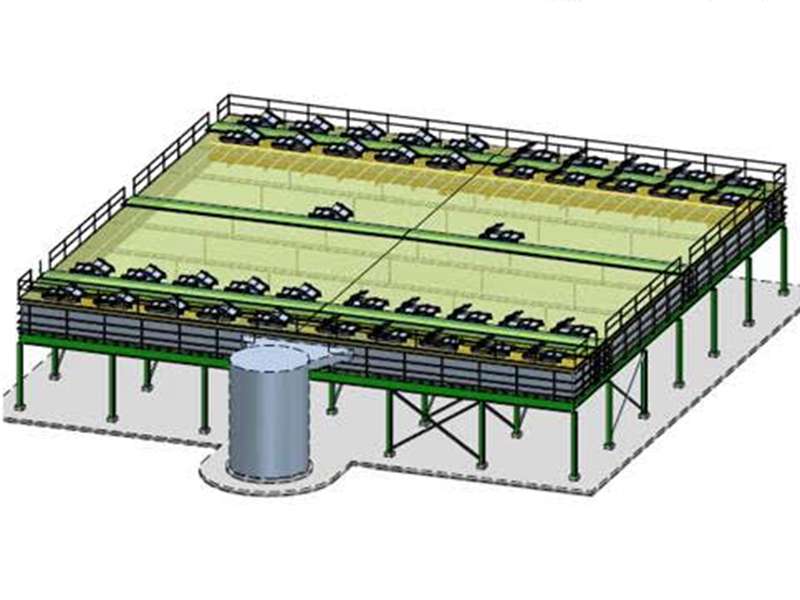

Another area of growth is the use of fiberglass in the industrial sector for corrosion-resistant applications. Chemical processing industries benefit immensely from fiberglass-reinforced plastics (FRP), which offer a robust alternative to traditional materials like steel and aluminum. FRP can withstand harsh chemicals, extreme temperatures, and corrosive environments, making it ideal for tanks, piping, and other infrastructure.

In the world of consumer products, fiberglass plays a prominent role in sports equipment, including surfboards, bicycles, and automotive parts. The ability to mold fiberglass into complex shapes while keeping weight low has led to its popularity in crafting high-performance gear.

In conclusion, fiberglass chemical products are at the forefront of materials science, providing solutions that are not only efficient but also versatile and increasingly sustainable. As research and development continue in this field, we can expect even more innovative applications and formulations that will further solidify fiberglass's position as a fundamental material in various sectors. From enhancing the durability of everyday products to supporting advanced technological applications, the future of fiberglass chemical products looks promising, paving the way for an exciting era in material engineering.