-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

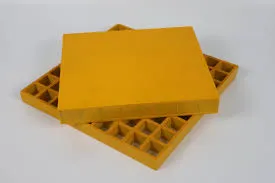

fiberglass fitting

Understanding Fiberglass Fittings A Comprehensive Overview

Fiberglass fittings are essential components in various industries, particularly in construction, marine applications, and the manufacturing of chemical processing equipment. These fittings, made from a composite of glass fibers and resin, offer a combination of strength, durability, and corrosion resistance that makes them ideal for a wide range of applications.

One of the primary advantages of fiberglass fittings is their lightweight nature. Compared to traditional materials like metal and concrete, fiberglass is significantly lighter, which simplifies transportation and installation. This characteristic is especially beneficial in marine environments, where weight reduction can enhance the performance of boats and ships. Additionally, fiberglass fittings do not corrode in salty or harsh environments, making them a preferred choice for marine applications, including piping and storage tanks.

Moreover, fiberglass fittings exhibit excellent chemical resistance. In industries that handle corrosive substances, such as pharmaceuticals and petrochemicals, using fiberglass can prevent deterioration and extend the lifespan of the equipment. This durability translates to lower maintenance costs and fewer replacements over time, presenting a cost-effective solution for businesses.

fiberglass fitting

The manufacturing process of fiberglass fittings involves layering glass fibers with a resin mixture. This layering technique creates a strong bond that enhances the fitting’s structural integrity. Different types of resins, such as epoxy or polyester, can be used to suit specific environmental conditions and application requirements. When these materials are properly cured, they form a sturdy yet flexible product that can withstand significant stress and strain.

Fiberglass fittings are available in various shapes and sizes, allowing them to be tailored to specific projects. Common types include elbows, tees, reducers, and flanges. The versatility of these fittings enables their use in a variety of systems, including plumbing, HVAC, and industrial processing.

Furthermore, the installation of fiberglass fittings is relatively straightforward, often requiring fewer specialized tools compared to metal fittings. This ease of installation not only saves time but also reduces labor costs, making fiberglass a practical choice for engineers and contractors.

In conclusion, fiberglass fittings are a vital aspect of modern infrastructure, known for their lightweight, corrosion-resistant, and durable characteristics. Whether used in marine settings, industrial facilities, or residential construction, these fittings provide a reliable solution for ensuring the integrity and functionality of various systems. As industries continue to innovate, the demand for fiberglass fittings is likely to grow, solidifying their role as a cornerstone in manufacturing and construction technologies.