-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Fiberglass Food Grade Equipment | Features & Benefits

A Closer Look at Fiberglass Food Grade Equipment Features and Benefits

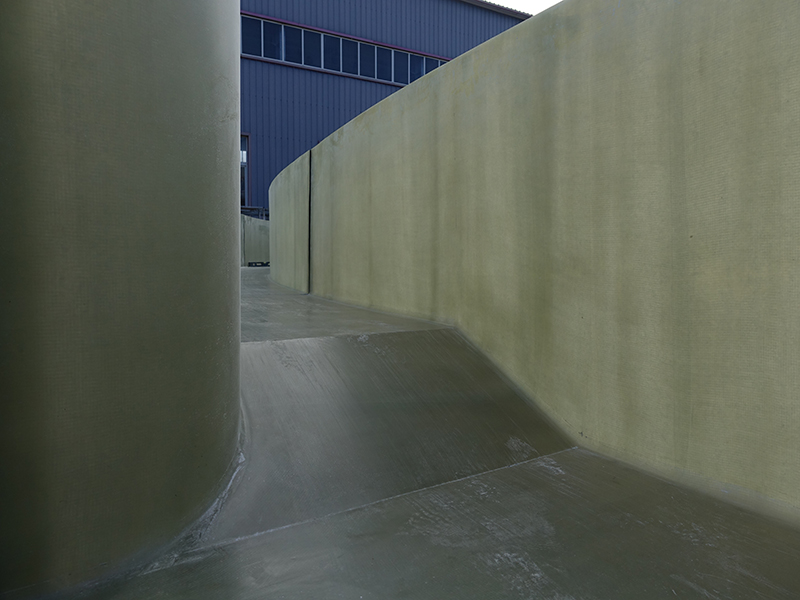

In the world of food processing and handling, maintaining safety and hygiene is paramount. One material that has gained significant recognition for its utility in the food industry is fiberglass. Fiberglass food grade equipment is designed to meet stringent health and safety standards while offering unique features that set it apart from traditional materials.

What is Fiberglass Food Grade Equipment?

Fiberglass, a composite material made from fine glass fibers and resin, is lauded for its lightweight and durable nature. Food grade fiberglass is specifically formulated to be safe for food contact, ensuring that it does not leach harmful substances into food products. This makes it an excellent choice for a variety of equipment used in food processing, storage, and transportation.

Key Features of Fiberglass Food Grade Equipment

1. Durability One of the standout features of fiberglass is its durability. Unlike metal or plastic components, fiberglass is resistant to rust, corrosion, and impact. This longevity reduces the need for frequent replacements, which can save businesses both time and money.

2. Weight Fiberglass is significantly lighter than many traditional materials. This lightweight nature enhances mobility and ease of handling, making it easier for workers to move equipment around, which is particularly beneficial in dynamic food processing environments.

fiberglass food grade equipment a closer look at its features and

3. Thermal Insulation Fiberglass exhibits excellent thermal insulating properties, which is crucial in food handling. It helps maintain temperature control during storage and transportation, thus preserving the quality and safety of food products.

4. Easy to Clean Hygiene is critical in the food industry, and fiberglass is non-porous, making it easy to clean and sanitize. The smooth surface prevents the accumulation of bacteria and other contaminants, ultimately helping to maintain food safety.

5. Customization Fiberglass can be molded into various shapes and sizes, allowing for customization to meet specific operational needs. This versatility ensures that businesses can get equipment tailored to their processes, enhancing efficiency and effectiveness.

Applications in the Food Industry

Fiberglass food grade equipment finds applications in numerous areas, including but not limited to food storage tanks, conveyor components, processing equipment, and even countertops in commercial kitchens. Its resilience and safety features make it suitable for both wet and dry applications, offering unparalleled flexibility.

Conclusion

In conclusion, fiberglass food grade equipment is revolutionizing the food industry by providing a safe, durable, and efficient alternative to traditional materials. Its unique features—such as durability, weight, thermal insulation, ease of cleaning, and customization—make it particularly well-suited for food-related applications. As food safety continues to be a top priority, the incorporation of fiberglass equipment will likely grow, ushering in a new standard for food processing and handling solutions. By choosing fiberglass, businesses can enhance their operational efficiency while ensuring compliance with health and safety regulations.