-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

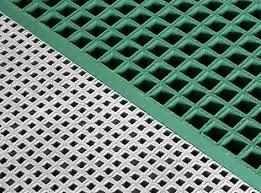

Fiberglass 90 Degree Elbow Specifications and Applications for Piping Systems

Understanding Fiberglass 90 Degree Elbows A Comprehensive Overview

Fiberglass has become a widely embraced material in various industries due to its remarkable properties, including resistance to corrosion, light weight, and high tensile strength. Among the many components made from fiberglass, the 90-degree elbow stands out as a crucial fitting in piping systems. This article delves into the significance, applications, manufacturing processes, and advantages of fiberglass 90-degree elbows.

What is a Fiberglass 90 Degree Elbow?

A fiberglass 90-degree elbow is a type of pipe fitting that is used to create a sharp change in direction within a piping system. As the name suggests, it changes the flow direction of liquids or gases by 90 degrees. These elbows are essential in plumbing, HVAC systems, chemical processing, and various other applications where precise flow control is required.

Applications of Fiberglass 90 Degree Elbows

The versatility of fiberglass 90-degree elbows allows for their use in several settings

1. Chemical Processing Fiberglass offers exceptional resistance against aggressive chemicals. In industries involving the transport of corrosive substances, fiberglass elbows ensure safety and longevity of the piping infrastructure.

2. Water Treatment Facilities These elbows are ideal for use in water treatment applications due to their rust-resistant properties, helping to maintain the integrity of the system over time.

3. Marine Applications In marine environments, fiberglass elbows prove valuable as they can withstand harsh conditions, including saltwater and exposure to UV rays.

4. HVAC Systems In heating, ventilation, and air conditioning systems, fiberglass elbows are used to guide airflow efficiently, contributing to the overall functionality of the system.

Manufacturing Process

The manufacturing of fiberglass 90-degree elbows typically involves a process known as filament winding or hand lay-up. Here’s a brief overview of the steps involved

1. Material Preparation The main materials used in the production are fiberglass strands and resin. The chosen resin plays a critical role, as it dictates the chemical resistance and durability of the final product.

fiberglass 90 degree elbow

2. Molding The prepared fiberglass is shaped into the desired elbow configuration using molds that meet the specific dimensions required by the application.

3. Curing Once the molding process is complete, the fittings are subjected to a curing process, where the resin hardens and binds the fiberglass strands together, ensuring a robust and durable product.

4. Finishing After curing, the elbows may undergo additional finishing processes, such as sanding or coating, to enhance their surface quality and facilitate seamless installation.

Advantages of Fiberglass 90 Degree Elbows

Choosing fiberglass 90-degree elbows over traditional materials like metal or PVC comes with several benefits

1. Corrosion Resistance Fiberglass is inherently resistant to corrosion, making these elbows a reliable choice for transporting corrosive fluids without fear of degradation.

2. Lightweight Compared to metal fittings, fiberglass elbows are significantly lighter, which simplifies installation and reduces the overall weight of piping systems.

3. Durability Fiberglass elbows offer excellent tensile strength, enabling them to withstand high pressures and temperatures, thus prolonging their lifespan.

4. Thermal Insulation The insulating properties of fiberglass prevent heat loss in transport systems, enhancing energy efficiency.

5. Customizability Fiberglass elbows can be manufactured in various sizes, shapes, and degrees of bend, allowing for extensive customization to meet specific operational needs.

Conclusion

Fiberglass 90-degree elbows are an essential component in modern piping systems, providing a solution that balances strength, weight, and resistance to corrosive environments. Their versatility across numerous applications, combined with a robust manufacturing process, ensures that they remain a preferred choice for engineers and construction professionals alike. By understanding the advantages and applications of fiberglass elbows, industries can make informed decisions, leading to enhanced operational efficiency and reliability in their systems. Whether in a chemical plant or a water treatment facility, the role of fiberglass fittings cannot be understated, marking a significant advancement in piping technology.