-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovation in Automotive Design Trends Utilizing Fiberglass for Lightweight Vehicles

The Rise of Fiberglass Cars A Testament to Innovation

In the realm of automotive engineering, the materials used in vehicle construction play a crucial role in determining performance, durability, and cost. Among these materials, fiberglass has emerged as a revolutionary choice, redefining what is possible in car design since its introduction in the mid-20th century. This lightweight, versatile composite material has allowed manufacturers to create vehicles that are not only functional but also aesthetically pleasing, changing the landscape of the auto industry.

Fiberglass, a composite material made from fine glass fibers woven into a resin matrix, offers an impressive combination of strength and lightness. This quality became particularly evident in the 1950s, when the introduction of fiberglass car bodies allowed for significant advancements in design and performance. Before fiberglass, automotive bodies were predominantly crafted from steel, which, while strong, was heavy and prone to rust. The shift to fiberglass reduced the overall weight of vehicles, which in turn led to enhanced fuel efficiency and improved handling.

One of the most iconic examples of the use of fiberglass in automotive design is the Chevrolet Corvette. First introduced in 1953, the Corvette captured the imagination of car enthusiasts with its sleek lines and impressive performance. Utilizing a fiberglass body, it not only showcased the possibilities offered by this innovative material but also set a standard for sports car design that would influence countless models in the decades to follow. The Corvette's lightweight construction allowed for a powerful engine configuration, leading to a performance vehicle that stood out in a competitive market.

The advantages of fiberglass go beyond weight reduction. Its resistance to corrosion and denting makes it an ideal choice for automotive applications, particularly in regions exposed to harsh weather conditions. This quality extends the lifespan of vehicles and reduces maintenance costs for consumers. Additionally, the ability to mold fiberglass into complex shapes allows designers to experiment with aerodynamic profiles that would be challenging or impossible with traditional materials.

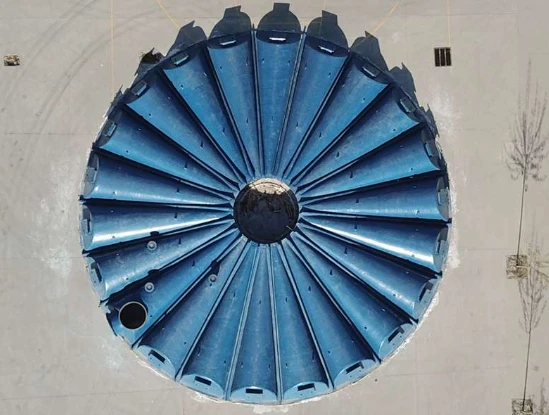

fiberglass car

As the automotive industry faces increasing pressure to reduce emissions and switch to sustainable materials, fiberglass presents a unique opportunity. Its lightweight properties contribute to lower fuel consumption, while advances in production technology continue to improve its environmental profile. Many manufacturers are now investigating bio-based resins to replace traditional petrochemical options, further enhancing fiberglass's appeal as a green material.

In addition to its functional benefits, fiberglass also plays a crucial role in the custom car scene and motorsports. Enthusiasts appreciate the material for its ease of repair and modification, allowing for highly personalized vehicles. From classic hot rods to modern race cars, the use of fiberglass has enabled builders to create visually stunning and performance-driven machines that stand out in a crowded market. Customization has become an integral part of car culture, and fiberglass serves as a fundamental component in the creation of unique automotive expressions.

However, the fiberglass car market is not without its challenges. While it offers numerous advantages, the production and repair of fiberglass vehicles require specialized skills and knowledge. As such, the labor involved can sometimes increase costs compared to traditional steel-bodied cars. There is also the need for proper disposal and recycling methods for fiberglass materials, which can be less straightforward than those for metal counterparts.

Despite these hurdles, the future of fiberglass cars looks promising. The material's adaptability appeals to an ever-evolving industry that values innovation and efficiency. As electric vehicles (EVs) become more prevalent, the lightweight properties of fiberglass could be pivotal in maximizing battery range and performance, making it an essential material for the next generation of automobiles.

In conclusion, the rise of fiberglass cars represents a significant evolution in automotive design and engineering. With their lightweight, corrosion-resistant properties and design flexibility, fiberglass vehicles have carved out a niche that bridges performance, sustainability, and customization. As we look to the future, it is clear that fiberglass will continue to play a vital role, pushing the boundaries of what is possible in the automotive landscape. The journey of fiberglass in the automotive world is far from over, and it promises to keep captivating both manufacturers and car enthusiasts for years to come.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025