-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Solutions in Fiberglass Chemical Products for Enhanced Performance and Durability

The Versatility of Fiberglass Chemical Products

Fiberglass, a composite material consisting of finely woven fibers and resins, has revolutionized numerous industries due to its remarkable properties. It combines strength, lightweight characteristics, and resistance to corrosion, making it an ideal choice for various applications, from construction to automotive manufacturing. The chemical products associated with fiberglass play a critical role in its performance, durability, and functionality.

Understanding Fiberglass Composition

At its core, fiberglass is made of glass fibers embedded in a polymer matrix, typically epoxy or polyester resin. This combination results in a material that not only boasts high tensile strength but is also flexible enough to be molded into complex shapes. The glass fibers provide structural integrity, while the resin acts as a binding agent, ensuring the fibers hold together and retain their properties over time.

The chemical processes involved in creating fiberglass are crucial. The production of fiberglass begins with the melting of silica and other raw materials, which is then extruded into glass fibers. These fibers are drawn into thin strands and woven into mats or fabrics. The selection of resin also impacts the final product's characteristics, including its thermal resistance, chemical resistance, and overall durability.

Applications of Fiberglass Chemical Products

Fiberglass chemical products have found extensive applications across different sectors. In construction, fiberglass-reinforced concrete is used for its lightweight yet strong properties, making it suitable for structures where traditional materials may be too heavy. This form of concrete also offers superior resistance to environmental factors, reducing maintenance costs over time.

The automotive industry extensively utilizes fiberglass in the manufacturing of car bodies and components. Fiberglass not only helps in reducing vehicle weight, which improves fuel efficiency but also enhances crash safety due to its energy-absorbing properties. Parts such as bumpers, hoods, and fenders made from fiberglass are popular for OEM parts and aftermarket upgrades.

In aerospace, fiberglass plays a crucial role in creating lightweight components that do not compromise strength. It is often used in aircraft interiors, fairings, and even support structures, helping to meet stringent weight requirements while maintaining safety standards.

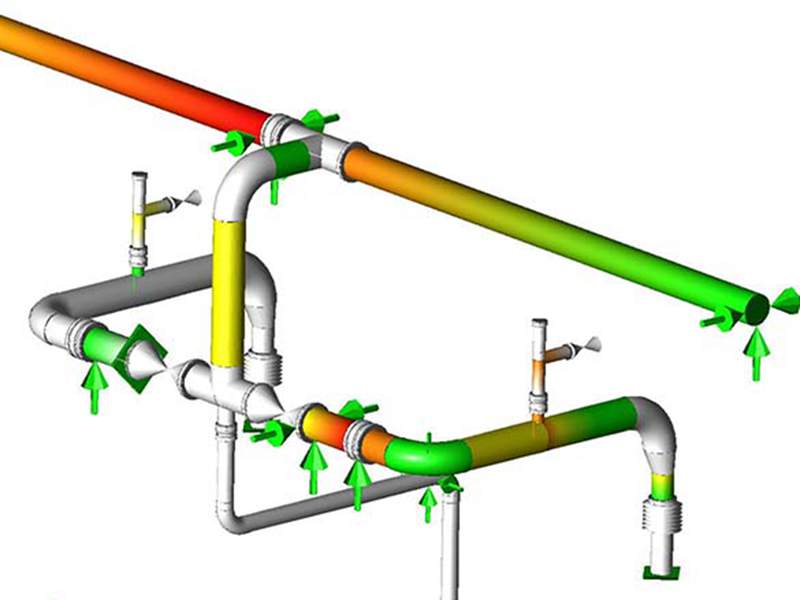

fiberglass chemical product

Advantages of Fiberglass Chemical Products

One of the most significant advantages of fiberglass is its resistance to corrosion, making it an ideal material for applications exposed to harsh environments. Industries like marine, chemical processing, and wastewater treatment rely on fiberglass products to avoid the deterioration that metals and other materials would suffer in these conditions.

Fiberglass is also a cost-effective solution. While the initial manufacturing processes may require significant investment, the long lifespan, low maintenance needs, and energy efficiency of fiberglass products often lead to cost savings over time. Additionally, its lightweight nature can result in reduced shipping costs, further enhancing its economic appeal.

Future Trends in Fiberglass Chemical Products

As technology advances, the production methods and applications of fiberglass continue to evolve. Innovations such as the development of bio-based resins and enhanced composite materials promise to make fiberglass even more sustainable. The increasing demand for environmentally friendly materials is pushing manufacturers to explore alternatives that maintain the desirable properties of fiberglass while reducing environmental impact.

Furthermore, advancements in recycling technologies for fiberglass materials are underway. This not only addresses concerns about waste generated by fiberglass products but also contributes to a circular economy, where materials are reused and repurposed rather than discarded.

Conclusion

Fiberglass chemical products exemplify how materials science can lead to innovative solutions across multiple industries. With their unique properties and versatility, fiberglass and its associated chemical products are set to remain vital components in construction, automotive, aerospace, and beyond. As we move toward a more sustainable future, the development of eco-friendly fiberglass solutions will undoubtedly play a crucial role in meeting both industrial needs and environmental challenges.