-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

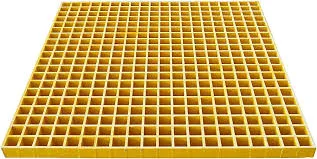

Durable and Lightweight Fiberglass Chemical Storage Solutions for Various Applications

The Versatility and Advantages of Fiberglass Chemical Tanks

In industrial applications, the storage and transportation of chemicals is vital for operational efficiency and safety. One solution that has gained significant popularity is the use of fiberglass chemical tanks. These tanks, constructed from a composite material that includes glass fibers and resin, offer numerous advantages over traditional storage options. This article explores the benefits, applications, and considerations of using fiberglass chemical tanks in various industries.

What are Fiberglass Chemical Tanks?

Fiberglass chemical tanks are storage containers made from fiberglass reinforced plastic (FRP). This material consists of glass fibers embedded in a resin matrix, providing strength, durability, and resistance to harsh environmental conditions. The combination of these materials results in a lightweight yet robust tank that can withstand various chemical substances.

Advantages of Fiberglass Chemical Tanks

1. Corrosion Resistance One of the most significant benefits of fiberglass chemical tanks is their excellent resistance to corrosion. Unlike metal tanks, which can rust or corrode when exposed to certain chemicals, fiberglass tanks do not suffer from degradation due to chemical reactions. This property extends the lifespan of the tanks and minimizes maintenance costs, ensuring they remain safe and effective for long-term use.

2. Lightweight and Easy to Install Fiberglass tanks are considerably lighter than their metal counterparts. This characteristic not only makes them easier to transport but also simplifies installation. Reduced weight can contribute to lower structural requirements for foundations and supports, ultimately leading to cost savings during the installation process.

3. Customizable Designs Fiberglass manufacturing allows for a high degree of customization. Tanks can be designed in various shapes, sizes, and configurations to meet specific storage needs. This flexibility is particularly beneficial for industries with unique requirements that standard tanks cannot fulfill.

4. Thermal Insulation Fiberglass tanks provide excellent thermal insulation properties. This feature is crucial for industries that store temperature-sensitive chemicals, as it helps maintain stable temperatures and prevent chemical reactions that may occur due to temperature fluctuations. Additionally, this quality can enhance energy efficiency in processes that require controlled environments.

5. Non-Toxic and Safe The materials used in fiberglass tanks are often non-toxic, making them a safe choice for storing chemicals without contamination. Manufacturers can also incorporate safety features, such as leak detection systems, ensuring peace of mind for operators handling hazardous materials.

Applications of Fiberglass Chemical Tanks

Fiberglass chemical tanks find their applications across various industries, including

fiberglass chemical tanks

- Water Treatment In water treatment facilities, fiberglass tanks are commonly used to store chemicals such as chlorine, sodium hypochlorite, and other water purification agents

. Their corrosion resistance and safe storage properties make them ideal for this application.- Chemical Manufacturing In the chemical industry, fiberglass tanks are utilized for storing bulk chemicals, intermediates, and finished products. Their customization capabilities allow manufacturers to conform to specific requirements for different chemicals.

- Agriculture Fiberglass tanks are extensively used in agricultural applications for storing fertilizers and pesticides. Their non-reactive nature ensures that the stored substances maintain their efficacy.

- Oil and Gas In the oil and gas sector, fiberglass tanks are employed for storing produced water and various chemicals used in drilling and production processes. Their resistance to harsh chemicals enables them to perform efficiently in challenging environments.

Considerations When Choosing Fiberglass Chemical Tanks

While fiberglass chemical tanks offer many advantages, several factors should be considered when selecting these storage solutions.

1. Chemical Compatibility Not all chemicals are compatible with fiberglass. It is essential to assess the specific chemical properties and ensure that the fiberglass composition can handle the intended substances without deterioration.

2. Regulatory Compliance Depending on the industry and location, fiberglass tanks must comply with specific regulations governing chemical storage and safety. Consulting with local authorities and adhering to industry standards is crucial to ensure compliance.

3. Maintenance and Inspection Although fiberglass tanks require less maintenance than metal tanks, regular inspections are still necessary to ensure their integrity and identify any potential issues.

Conclusion

Fiberglass chemical tanks represent a significant advancement in the field of chemical storage. Their corrosion resistance, lightweight design, thermal insulation, and customizable features make them suitable for various applications across industries. By understanding the benefits and considerations associated with fiberglass tanks, businesses can make informed decisions that enhance storage safety and efficiency in their operations. As technology continues to evolve, fiberglass chemical tanks are likely to remain a top choice for industrial storage solutions, contributing to safer and more sustainable practices in chemical management.