-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

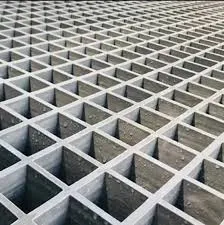

Fiberglass Clarifier Solutions for Enhanced Water Treatment and Solid Removal Efficiency

Fiberglass Clarifier System for Efficient Water Treatment and Solid Separation

In recent years, the demand for efficient water treatment systems has significantly increased due to growing environmental concerns and stringent regulations. Among various technologies, fiberglass clarifier systems have emerged as an innovative solution, offering enhanced performance in water treatment and solid separation processes. This article explores the advantages of fiberglass clarifier systems, their operational mechanisms, and their applications in various industries.

What is a Fiberglass Clarifier System?

A fiberglass clarifier system is an advanced water treatment technology designed to remove suspended solids and contaminants from wastewater. These systems utilize a combination of gravitational settling and flotation processes to separate solids from liquids. The key advantage of using fiberglass in these systems lies in its lightweight, corrosion-resistant properties, making it an ideal material for constructing tanks and components.

Advantages of Using Fiberglass in Clarifier Systems

1. Durability and Longevity One of the most significant benefits of fiberglass is its resistance to corrosion and wear. Unlike traditional materials like steel or concrete, fiberglass does not rust or degrade over time, ensuring a longer lifespan and reduced maintenance costs.

2. Lightweight Design The lightweight nature of fiberglass simplifies installation and transportation. This characteristic not only reduces labor costs but also allows for flexibility in system design and placement, making it easier to integrate into existing facilities.

3. Cost-Effectiveness While the initial investment in fiberglass clarifiers may be higher than other materials, the long-term savings in maintenance, operational efficiency, and prolonged equipment life can result in overall cost-effectiveness.

4. Customized Solutions Fiberglass clarifier systems can be tailored to meet specific treatment needs, accommodating various flow rates and contaminant loads. This customization ensures optimal performance, regardless of the application.

How Fiberglass Clarifier Systems Work

The operation of a fiberglass clarifier system typically involves several key stages

fiberglass clarifier system for efficient water treatment and solid

1. Influent Distribution Wastewater enters the clarifier through an influent distribution system, which evenly disperses the flow across the surface area of the clarifier.

2. Settling Zone As the wastewater flows through the clarifier, heavier solids settle to the bottom due to gravity, forming a sludge layer. This zone is designed to maximize the settling process, allowing for effective solid removal.

3. Sludge Removal The accumulated sludge is periodically removed from the bottom of the clarifier using manual or automated systems. This process helps maintain optimal performance and prevents the buildup of solids that could hinder efficiency.

4. Clarified Effluent The upper layer of the clarifier, where clearer water accumulates, is drained off. This treated water can then be discharged or sent for further treatment, depending on regulatory requirements and intended reuse.

5. Optional Flotation Some fiberglass clarifiers may include a flotation mechanism, which introduces air bubbles into the wastewater. These bubbles attach to lighter solid particles, causing them to rise to the surface for removal, further enhancing the solids separation process.

Applications of Fiberglass Clarifier Systems

Fiberglass clarifier systems find applications across various industries, including

- Municipal Water Treatment Used in wastewater treatment plants to ensure that effluent meets environmental discharge standards. - Industrial Processes Effective in treating process water in industries such as manufacturing, chemical processing, and food and beverage production. - Aquaculture Employed in fish farming operations to maintain water quality and promote healthy aquatic environments. - Mining and Mineral Processing Used for the treatment of water from mining operations, helping to manage sediment and prevent environmental contamination.

Conclusion

The fiberglass clarifier system stands out as a robust, efficient, and customizable solution for contemporary water treatment challenges. Its unique properties provide numerous benefits that enhance the overall effectiveness of wastewater management. As industries continue to prioritize sustainability and regulatory compliance, fiberglass clarifiers are poised to play an essential role in the future of water treatment technologies. With ongoing advancements in design and application, these systems represent a significant step forward in achieving efficient water treatment solutions worldwide.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025