-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

fiberglass clarifier system for efficient water treatment and solid ...

Fiberglass Clarifier System for Efficient Water Treatment and Solid Removal

In our modern society, the need for efficient water treatment systems has never been more critical. As urban populations expand and industrial activities increase, the demand for clean water and effective waste management rises sharply. One innovative solution to address these challenges is the fiberglass clarifier system, a state-of-the-art technology designed to enhance water treatment processes and ensure optimal solid removal.

Fiberglass clarifiers are advanced structures that utilize the principles of sedimentation to separate solids from liquids in various water treatment applications. The primary function of these systems is to provide high efficiency in clarifying water, making them indispensable in industries such as municipal wastewater treatment, industrial effluent management, and stormwater management.

One of the standout features of fiberglass clarifiers is their lightweight and corrosion-resistant nature. Traditional clarifiers made from materials like steel often succumb to rust and degradation over time, especially when exposed to harsh chemicals and environmental conditions. In contrast, fiberglass is engineered to withstand such challenges, offering a longer service life and reduced maintenance costs. This characteristic is particularly beneficial for facilities that require longevity and reliability in their water treatment equipment.

The design of fiberglass clarifiers also contributes to their efficiency. These systems typically feature a more compact footprint compared to traditional concrete or metal clarifiers. This compact design allows for easier installation and integration into existing treatment plants without the need for extensive modifications. Furthermore, the streamlined shape of fiberglass clarifiers enhances hydraulic flow, ensuring better sedimentation and separation of solids from the water.

fiberglass clarifier system for efficient water treatment and solid ...

The operational mechanism of a fiberglass clarifier revolves around the process of gravity settling. When raw wastewater or stormwater enters the clarifier, the heavier solid particles settle at the bottom, forming a sludge layer. Meanwhile, the clarified water rises to the top and is collected for further treatment or discharge. By optimizing detention time and maintaining appropriate flow rates, fiberglass clarifiers can achieve impressive solid removal rates, often exceeding 90%. This high level of efficiency is crucial for meeting regulatory standards and ensuring environmental protection.

Moreover, fiberglass clarifier systems are designed with additional features that enhance their performance. Many models include innovative mechanisms such as adjustable weirs, which allow operators to control the water level and optimize the removal of solids. Some systems even incorporate advanced monitoring technologies that track the performance metrics in real-time, enabling facility managers to make informed decisions and adjustments as needed.

The applications of fiberglass clarifier systems extend beyond municipal and industrial uses. They are also ideal for treating agricultural runoff, which often carries sediment, nutrients, and other pollutants that can harm local ecosystems. By employing efficient solid removal techniques, fiberglass clarifiers play a vital role in sustainable water management practices, promoting cleaner waterways and healthier environments.

In summary, the fiberglass clarifier system represents a significant advancement in water treatment technology. Its robust construction, efficient design, and operational effectiveness make it an ideal choice for various industries seeking to improve their water treatment processes and achieve superior solid removal. As water scarcity and environmental concerns continue to mount, the adoption of such innovative systems will be essential for ensuring a sustainable future for our planet's water resources.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

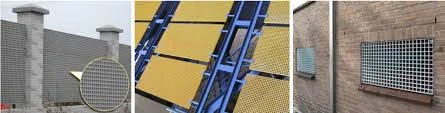

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025