-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

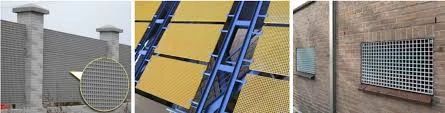

fiberglass cover

The Versatile World of Fiberglass Covers

Fiberglass covers have transformed a variety of industries through their unique properties and applications. Known for their strength, durability, and resistance to corrosion, fiberglass covers have become a go-to solution for many professionals seeking reliable protection and aesthetic appeal.

What is Fiberglass?

Fiberglass is a composite material made from fine strands of glass fibers embedded in a resin matrix. The result is a lightweight, yet incredibly strong substance. It is resistant to environmental factors such as water, UV rays, and chemicals, making it an ideal choice for outdoor applications. Easy to mold into complex shapes, fiberglass offers versatility that many other materials simply cannot match.

Applications of Fiberglass Covers

1. Industrial Use In industrial settings, fiberglass covers are commonly used for machinery and equipment protection. They shield vital components from dust, moisture, and other contaminants that could hinder machine performance. Moreover, their resistance to chemicals makes them suitable for use in laboratories and manufacturing facilities.

2. Construction The construction industry utilizes fiberglass covers for roofing and cladding. These covers provide excellent insulation, can be colored or coated for aesthetic purposes, and are lighter than traditional materials, reducing transportation and installation costs. They are especially valuable in environments where traditional materials may degrade due to weather conditions.

3. Automotive & Marine Fiberglass covers are prominent in the automotive and marine industries as well. They are often used for body panels, hoods, and even boat hulls due to their aerodynamic properties and lightweight nature. The use of fiberglass helps improve fuel efficiency and handling while allowing for creative designs.

fiberglass cover

4. Consumer Products In everyday life, fiberglass covers are found in various consumer products such as outdoor furniture, storage containers, and even swimming pool covers. With their ability to withstand harsh weather and UV exposure, they maintain their appearance and functionality over time, appealing to those who seek durability in their purchases.

Advantages of Fiberglass Covers

One of the most significant advantages of fiberglass covers is their combination of strength and weight. They provide exceptional durability without the heft associated with metals or traditional plastics. This makes them easier to handle and install.

Fiberglass is also a non-conductive material, making it a safe choice for electrical applications. This property protects both users and the equipment from electrical hazards, thus ensuring safety in industrial and home environments alike.

Another critical benefit lies in their low maintenance requirements. Unlike wood or metal, fiberglass does not rot, rust, or require frequent painting. A simple cleaning with soap and water can keep them looking new for years, much to the delight of both manufacturers and consumers.

The Future of Fiberglass Covers

As technology continues to advance, the future of fiberglass covers appears bright. Innovations in resin formulations and manufacturing processes are enhancing the strength and sustainability of these materials. Furthermore, with the global push towards eco-friendly solutions, researchers are exploring bio-based resins that can further improve the environmental impact of fiberglass production.

In conclusion, fiberglass covers represent an excellent option for a range of applications across multiple industries. Their combination of strength, durability, and versatility makes them a preferred choice for professionals and consumers alike. As advancements in technology continue to refine this material, we can expect even greater uses and innovations in the world of fiberglass covers in the years to come. Whether for industrial, construction, or consumer needs, fiberglass covers have truly proven to be an invaluable resource.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025