-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

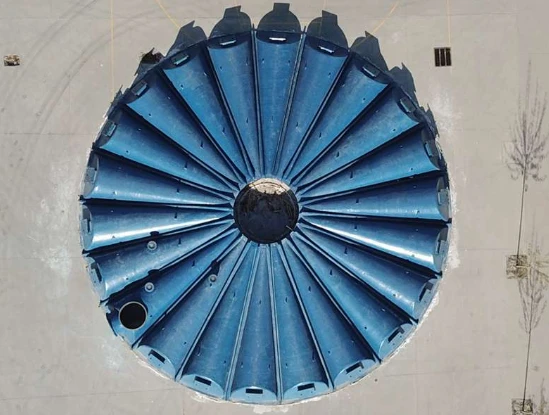

Custom Fiberglass Fittings Tailored to Your Unique Needs and Specifications

The Versatility of Fiberglass Customized Fittings

In recent years, fiberglass has emerged as a pivotal material in various industries due to its remarkable properties. One area where fiberglass excels is in the production of customized fittings, which are essential components in numerous applications, ranging from construction to automotive and beyond. This article delves into the benefits and applications of fiberglass customized fittings, highlighting their significance in today’s manufacturing landscape.

Fiberglass, a composite material made from glass fibers and resin, boasts a unique combination of lightweight strength, resistance to corrosion, and thermal insulation. These attributes make it an ideal choice for manufacturing customized fittings that can withstand harsh environments while maintaining structural integrity. Unlike traditional materials such as metal or PVC, fiberglass does not rust, rot, or corrode, which significantly extends the lifespan of fittings and reduces maintenance costs over time.

One of the key advantages of fiberglass customized fittings is the ability to tailor them according to specific requirements. Manufacturers can produce fittings in various shapes, sizes, and colors to meet the unique demands of every project. This level of customization is particularly beneficial in industries such as construction, where components need to fit seamlessly into an existing structure or system. For example, custom fiberglass elbows, tees, and flanges can be designed to ensure optimal flow and efficiency in piping systems.

In the realm of the chemical and wastewater industries, fiberglass fittings play a crucial role in ensuring safe and efficient operations. The resistance of fiberglass to harsh chemicals and its non-reactive nature make it an ideal material for tanks, pipes, and couplings used in these sectors. Customized fittings can be engineered for specific chemical applications, providing the necessary strength and resistance to prevent leaks and failures, which could result in catastrophic consequences.

fiberglass customized fittings

Additionally, fiberglass customized fittings are gaining traction in the automotive industry. With the push for lightweight materials to improve fuel efficiency and reduce emissions, manufacturers are increasingly turning to fiberglass composites. Custom-designed fittings can enhance performance while contributing to the overall reduction of vehicle weight. From brackets to enclosures, fiberglass components are becoming a staple in modern vehicle design.

Moreover, the construction industry benefits greatly from fiberglass fittings due to their ease of installation and versatility. Customized fittings can be pre-assembled off-site, reducing on-site labor and installation time. This efficiency is especially advantageous in large construction projects where time is of the essence. The ability to create bespoke solutions allows architects and engineers to push the boundaries of design, enabling innovative structures that incorporate complex shapes and features.

Sustainability is another factor driving the popularity of fiberglass customized fittings. With increased awareness of environmental issues, many industries are seeking materials that not only perform well but also have a lower ecological footprint. Fiberglass can be manufactured from recycled materials and is itself recyclable, making it a more sustainable option compared to traditional fittings made from metals or plastics.

In conclusion, fiberglass customized fittings offer unparalleled versatility and performance across various industries. Their lightweight strength, resistance to corrosion and chemicals, and potential for customization make them an invaluable asset in construction, automotive, and other sectors. As industries continue to evolve, the demand for innovative and sustainable solutions like fiberglass fittings will undoubtedly grow, paving the way for advancements in manufacturing and design. Whether it’s enhancing efficiency in operations or contributing to a more sustainable future, fiberglass customized fittings are poised to play a significant role in shaping the advancements of tomorrow.