-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

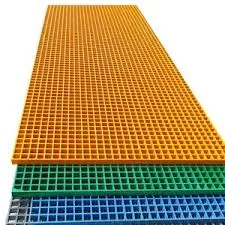

Customized Fiberglass Fittings for Your Unique Industry Needs and Applications

The Advantages of Fiberglass Customized Fittings

In the world of construction and industrial applications, the demand for durable and versatile materials is paramount. One such material that has gained significant popularity is fiberglass. Fiberglass, a composite material made of fine glass fibers, offers exceptional strength, lightweight properties, and resistance to corrosion. Fiberglass customized fittings have emerged as a game-changer in various industries, providing tailored solutions that meet the specific requirements of different projects.

Understanding Fiberglass

Fiberglass is composed of glass fibers woven together and then combined with a resin. The result is a lightweight yet robust material that can withstand the rigors of various environments. Its resistance to chemicals, moisture, and heat makes it an ideal choice for fittings in industries such as plumbing, construction, aviation, and automotive.

Benefits of Customized Fiberglass Fittings

1. Tailored Solutions One of the most significant advantages of fiberglass customized fittings is their ability to meet specific project needs. Every construction site or industrial application may have unique requirements, and generic fittings may not always suffice. Customized fittings can be designed to fit precise measurements, ensuring optimal performance and reducing the risk of leaks or failures.

2. Corrosion Resistance In many environments, especially those involving water or chemicals, corrosion can pose a serious risk to traditional metal fittings. Fiberglass fittings are inherently resistant to corrosion, which extends their lifespan and reduces maintenance costs. This resistance means that industries such as wastewater treatment plants, chemical processing facilities, and marine applications can benefit immensely from using fiberglass fittings.

3. Lightweight Yet Strong Unlike metal fittings, which can be heavy and cumbersome, fiberglass fittings are significantly lighter. This lightweight nature not only makes them easier to handle and install but also contributes to a reduction in transportation costs. Despite being lightweight, fiberglass provides superior strength-to-weight ratios, ensuring that the fittings can withstand substantial pressure and stress.

fiberglass customized fittings

4. Temperature Resistance Fiberglass fittings are designed to endure extreme temperatures, making them suitable for a wide range of applications. Whether it's in high-heat environments or freezing conditions, fiberglass fittings maintain their integrity and functionality, thus broadening their usability across different sectors.

5. Cost-Effectiveness While the initial investment in fiberglass custom fittings may be higher than traditional materials, the long-term savings often outweigh the upfront costs. The durability and low maintenance requirements of fiberglass result in reduced replacement costs and enhanced efficiency. Over time, businesses can experience significant cost savings, making fiberglass an economically viable option.

6. Eco-Friendly Option With an increasing emphasis on sustainability, fiberglass products stand out as environmentally friendly. The production process for fiberglass can be more sustainable than that of conventional fittings, and many manufacturers prioritize eco-friendly practices. Additionally, the longevity and recyclability of fiberglass contribute to a reduced environmental footprint.

Applications of Customized Fiberglass Fittings

Fiberglass customized fittings can be utilized in various sectors. In the construction industry, they can be used for piping systems, ventilation, and HVAC installations. In the water and wastewater treatment sector, fiberglass is preferred for its resistance to chemicals and moisture. Additionally, in marine applications, fiberglass fittings are ideal due to their lightweight and corrosion-resistant properties.

Conclusion

The use of fiberglass customized fittings is transforming the landscape of construction and industrial applications. Their tailored design, corrosion resistance, lightweight nature, and overall cost-effectiveness make them an attractive alternative to traditional materials. As industries continue to seek innovative solutions to complex challenges, fiberglass fittings are positioning themselves as a reliable choice. Whether for a large-scale industrial project or a small renovation, investing in fiberglass customized fittings could very well be the decision that enhances performance, reduces costs, and promotes sustainability in the long run. Embracing this advanced technology not only modernizes infrastructure but also paves the way for a more sustainable and efficient future.